Types of electric motors and the principles of their work

Imagine what the modern world would be like if all electric motors suddenly disappeared from it. Suppose we would replace them with heat engines. But heat engines are bulky, emit steam and exhaust gases, while electric motors of comparable power are compact, fit perfectly on machines, electric vehicles, and other equipment, while being environmentally friendly, economical, and reliable. It is impossible to imagine the modern world without electric motors, greatly facilitating the work of people, in short, making our life more comfortable.

Imagine what the modern world would be like if all electric motors suddenly disappeared from it. Suppose we would replace them with heat engines. But heat engines are bulky, emit steam and exhaust gases, while electric motors of comparable power are compact, fit perfectly on machines, electric vehicles, and other equipment, while being environmentally friendly, economical, and reliable. It is impossible to imagine the modern world without electric motors, greatly facilitating the work of people, in short, making our life more comfortable.

Thanks to electric motors, we get mechanical energy from electrical energy. And weight and size characteristics, power and the number of revolutions per minute are of decisive importance in this process, which in turn are associated with both the design features of the engines and the parameters of the supply voltage ...

How to disassemble an induction motor

Where only electric motors are not used today. Home appliances and cottage equipment, machine tools, power tools, electric vehicles and high-precision devices - everywhere you can find a small or large electric motor in one or another node of a device. Some of the readers may need to disassemble the engine for repair or maintenance, it is likely that this will need to be done at home. So let's see how the disassembly is done correctly.

Where only electric motors are not used today. Home appliances and cottage equipment, machine tools, power tools, electric vehicles and high-precision devices - everywhere you can find a small or large electric motor in one or another node of a device. Some of the readers may need to disassemble the engine for repair or maintenance, it is likely that this will need to be done at home. So let's see how the disassembly is done correctly.

In everyday life, you can find electric motors of two main types: asynchronous and collector. Induction motors are more often used in ventilation equipment, in machines, in pumps. Etc. Collector can be found in drills, in grinders and in other power tools. Collector ones are usually high-speed, while asynchronous ones have approximately a fixed synchronous frequency ...

Types and arrangement of revolutions of collector engine speed

Collector motors can often be found in household electrical appliances and in power tools: a washing machine, grinder, drill, vacuum cleaner, etc. Which is not at all surprising, because the collector motors allow you to get both high revolutions and high torque (including high starting torque ) - which is what is needed for most power tools.

Collector motors can often be found in household electrical appliances and in power tools: a washing machine, grinder, drill, vacuum cleaner, etc. Which is not at all surprising, because the collector motors allow you to get both high revolutions and high torque (including high starting torque ) - which is what is needed for most power tools.

In this case, the collector motors can be powered by both direct current (in particular, rectified) and alternating current from a household network. To control the rotational speed of the rotor of the collector motor, speed regulators are used, which will be discussed in this article. To begin with, recall the device and the principle of the collector motor. The collector motor necessarily includes the following parts: rotor, stator and brush-commutator switching unit. When power is supplied to the stator and rotor, their magnetic fields ...

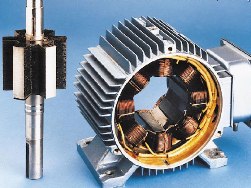

Squirrel cage and phase rotor - what is the difference

As you know, induction motors have a three-phase winding (three separate windings) of the stator, which can form a different number of pairs of magnetic poles depending on their design, which in turn affects the rated engine speed at the rated frequency of the supplying three-phase voltage. At the same time, the rotors of this type of motor may differ, and for asynchronous motors they are short-circuited or phase. What distinguishes a squirrel-cage rotor from a phase rotor - this will be discussed in this article.

As you know, induction motors have a three-phase winding (three separate windings) of the stator, which can form a different number of pairs of magnetic poles depending on their design, which in turn affects the rated engine speed at the rated frequency of the supplying three-phase voltage. At the same time, the rotors of this type of motor may differ, and for asynchronous motors they are short-circuited or phase. What distinguishes a squirrel-cage rotor from a phase rotor - this will be discussed in this article.

Ideas about the phenomenon of electromagnetic induction will tell us what will happen with a closed coil of a conductor placed in a rotating magnetic field, similar to the magnetic field of a stator of an induction motor. If such a coil is placed inside the stator, then when a current is supplied to the stator winding, EMF will be induced in the coil ...

Modern synchronous jet engines

In synchronous jet motors, the principle of creating a rotor torque is somewhat different from asynchronous and traditional synchronous motors.Here the decisive role is assigned to the rotor core itself.

In synchronous jet motors, the principle of creating a rotor torque is somewhat different from asynchronous and traditional synchronous motors.Here the decisive role is assigned to the rotor core itself.

The rotor of a jet synchronous motor does not have windings, even there is no short-circuited winding on it. Instead, the rotor core is made highly heterogeneous in magnetic conductivity: the magnetic conductivity along the rotor is different from the magnetic conductivity across. Thanks to this unusual approach, there is no need for both rotor windings and permanent magnets on it. As for the stator, the stator winding of the jet synchronous motor can be concentrated or distributed, while the stator core and housing remain normal. The whole feature is in the highly heterogeneous core of the rotor.For jet synchronous motors are characteristic ...

Mechanical and electrical characteristics of induction motors

This article will highlight the topic of mechanical and electrical characteristics of electric motors. Using an asynchronous motor as an example, consider such parameters as power, work, efficiency, cosine phi, torque, angular velocity, linear speed and frequency. All these characteristics are important when designing equipment in which electric motors serve as drive motors. Especially asynchronous electric motors are especially widespread in the industry today, so we will dwell on their characteristics. For example, consider the AIR80V2U3.

This article will highlight the topic of mechanical and electrical characteristics of electric motors. Using an asynchronous motor as an example, consider such parameters as power, work, efficiency, cosine phi, torque, angular velocity, linear speed and frequency. All these characteristics are important when designing equipment in which electric motors serve as drive motors. Especially asynchronous electric motors are especially widespread in the industry today, so we will dwell on their characteristics. For example, consider the AIR80V2U3.

The nameplate (on the nameplate) of the motor always indicates the rated mechanical power on the shaft of the motor. This is not the electric power that this electric motor consumes from the network. So, for example, for an AIR80V2U3 engine, a rating of 2200 watts corresponds precisely to the mechanical power on the shaft ...

Single-phase asynchronous motor: how it works

A single-phase electric motor is called one that works from a two-wire AC network, represented by a phase and zero potential. The number of windings mounted in various designs of stators does not affect this definition. According to its technical device, an induction motor consists of a stator - a static, fixed part made by a housing with various electrical elements located on it and a rotor rotated by the forces of the electromagnetic field of the stator.

The mechanical connection of these two parts is made by rotation bearings, the inner rings of which are mounted on the fitted sockets of the rotor shaft, and the outer rings are mounted in protective side covers fixed to the stator. The rotor device for these models is the same as for all induction motors: on a steel shaft mounted magnetic circuit from burdened plates based on soft iron alloys ...

How to check the status of the winding of an electric motor

At first glance, the winding is a piece of wire wound in a certain way and there is nothing much to break in it. But it has features: strict selection of homogeneous material along the entire length, accurate calibration of the shape and cross section, application of a varnish layer with high insulating properties in the factory, strong contact joints. If at any point in the wire any of these requirements is violated, the conditions for the passage of electric current change and the engine starts to work with reduced power or stops altogether.

At first glance, the winding is a piece of wire wound in a certain way and there is nothing much to break in it. But it has features: strict selection of homogeneous material along the entire length, accurate calibration of the shape and cross section, application of a varnish layer with high insulating properties in the factory, strong contact joints. If at any point in the wire any of these requirements is violated, the conditions for the passage of electric current change and the engine starts to work with reduced power or stops altogether.

To test one winding of a three-phase motor, disconnect it from other circuits. In all electric motors, they can be assembled according to one of two schemes: a star and a triangle. The ends of the windings are usually output to the terminal blocks and are marked with the letters "H" (beginning) and "K" (end). Sometimes individual compounds can be hidden ...