Categories: Novice electricians, Electric motors and their application

Number of views: 15482

Comments on the article: 1

Modern synchronous jet engines

The principle of operation of a synchronous jet engine

In synchronous jet motors, the principle of creating a rotor torque is somewhat different from asynchronous and traditional synchronous motors. Here the decisive role is assigned to the rotor core itself.

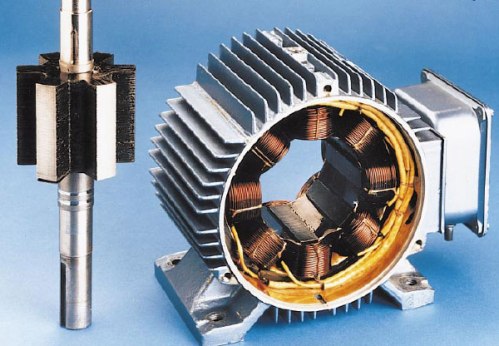

The rotor of a jet synchronous motor does not have windings, even there is no short-circuited winding on it. Instead, the rotor core is made highly heterogeneous in magnetic conductivity: the magnetic conductivity along the rotor is different from the magnetic conductivity across. Thanks to this unusual approach, there is no need for both rotor windings and permanent magnets on it.

As for the stator, the stator winding of the jet synchronous motor can be concentrated or distributed, while the stator core and housing remain normal. The whole feature is in the highly heterogeneous rotor core.

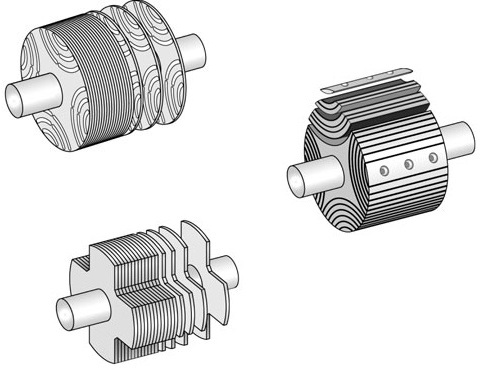

Three main types of rotors are characteristic of synchronous jet engines: a transversely stratified rotor, a rotor with distinct poles, and an axially stratified rotor.

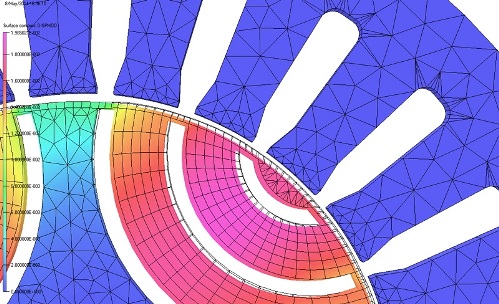

The physics of the process is as follows. Alternating current is supplied to the stator windings, and creates a rotating magnetic field around the rotor, which is maximum in the air gap between the stator and the rotor. The rotation moment is obtained due to the fact that the rotor tries to turn all the time so that the magnetic resistance for the magnetic flux generated by the stator would be minimal.

The maximum torque is directly proportional to the difference between the longitudinal and transverse inductances, and the larger this difference, the greater the torque of the rotor.

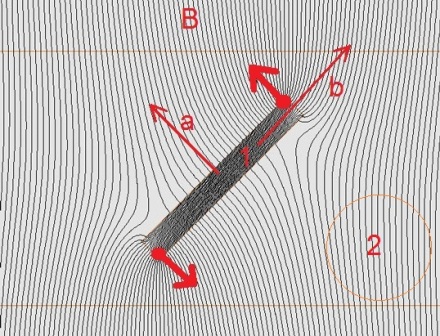

To understand this principle, we turn to the figure. Anisotropic object 1 has different magnetic conductivity along the axes a and b. In this case, the isotropic object 2 has the same magnetic conductivity in all directions. A magnetic field applied to object 1 generates a rotation moment when the angle between the axis b and the lines of magnetic induction B is not equal to zero. When a non-zero angle exists, object 1 will distort the applied magnetic field B, and the direction of distortion will coincide with the axis a of object 1.

The sinusoidal magnetic field created in the synchronous jet engine by the stator winding rotates with a certain synchronous angular frequency, and therefore there will always be a moment of rotation, which tends to return the system to the state with the lowest total potential energy.

That is, the rotation moment will always strive to reduce the distortion of the stator magnetic field in the direction of the a axis, by decreasing the angle between the induction lines B and the b axis. So, if engine control is aimed at maintaining the constancy of this angle, then mechanical energy will constantly be obtained from electromagnetic.

Thus, the stator winding current provides magnetization with the existence of a torque aimed at eliminating the distortion of the field, and by controlling the current phase in accordance with the position of the rotor in the rotating coordinate system (in accordance with the value of the distortion angle), the torque control of the synchronous jet motor is obtained.

Synchronous jet motors today

The world's leading manufacturers of electric motors today show particular interest in synchronous jet motors, although the first versions were patented back in the late 19th century. The fact is that the efficiency of synchronous jet motors fundamentally significantly exceeds Efficiency of popular induction motorsnot to mention power density.

There are no energy losses in the rotor, but usually the rotor accounts for about 30 percent of losses. This increases the life of the electric motor - reduces harmful heat. The mass of a synchronous jet motor and its dimensions are 20% less than that of an asynchronous same power.

The renewed interest in synchronous jet motors today is primarily associated with the wide capabilities of modern computer modeling, which allow finding the most effective versions of rotor and stator designs - scientific research is more productive, and the efficiency of modern versions of synchronous jet motors is already 98%, at that time as for asynchronous versions, the efficiency does not traditionally exceed 90%.

Synchronous jet engines are made today on the basis of asynchronous ones, and with the same dimensions and mounting dimensions, a higher efficiency is obtained, a higher specific power is achieved.

Advantages and disadvantages

Drawn from thin-sheet electrical steel, the rotor of a jet synchronous motor has a simple and reliable design without a short-circuited winding and without magnets, therefore, currents causing harmful heating are eliminated in the rotor - the service life is increased, and the absence of magnets reduces the cost of the product, including minimizing reduced maintenance costs .

Due to the comparative lightness of the rotor, its own moment of inertia is low, so the engine accelerates to nominal speed faster, which leads to energy savings.

The frequency inverter as a speed controller makes the motor control very flexible over a wide range of operating speeds. As for the shortcomings, it is only one: the need for a frequency converter.

The use of a frequency converter with active correction of the power factor allows achieving the maximum power factor of the system, which is very important in any modern production.

See also at i.electricianexp.com

: