Depending on the purpose, on the expected operating modes and conditions, on the type of power supply, etc., all electric motors can be classified according to several parameters: by the principle of obtaining the operating moment, by the method of operation, by the nature of the supply current, by the method of phase control, by type of excitation, etc. Let us consider the classification of electric motors in more detail.

Depending on the purpose, on the expected operating modes and conditions, on the type of power supply, etc., all electric motors can be classified according to several parameters: by the principle of obtaining the operating moment, by the method of operation, by the nature of the supply current, by the method of phase control, by type of excitation, etc. Let us consider the classification of electric motors in more detail.

Torque in electric motors can be obtained in one of two ways: by the principle of magnetic hysteresis or purely magnetoelectric. A hysteresis motor receives torque through the hysteresis during magnetization reversal of a magnetically solid rotor, while in a magnetoelectric motor the torque is the result of the interaction of the explicit magnetic poles of the rotor and stator. Magnetoelectric motors rightfully make up the lion's share of the total abundance of electric motors ...

It often happens, especially in everyday life, that an asynchronous electric motor must be connected to a standard single-phase AC network with an operating voltage of 220 volts. And the engine is three-phase! This task is typical when we need to install an emery or a drilling machine, for example, in a garage.

It often happens, especially in everyday life, that an asynchronous electric motor must be connected to a standard single-phase AC network with an operating voltage of 220 volts. And the engine is three-phase! This task is typical when we need to install an emery or a drilling machine, for example, in a garage.

To arrange everything correctly, they use the so-called starting and working (phase-shifting) capacitors. In general, capacitors are of different types, different capacities, and before proceeding with the construction of the circuit, it is necessary to select the capacitors of the appropriate type, rated voltage and correctly calculate their required capacitance. Everyone knows that an electric capacitor is two conductive plates separated by a dielectric, and serves to accumulate, temporarily store and transfer electric charge, that is, electric energy ...

How to determine the rotation speed of an electric motor

The speed of rotation of an induction motor is usually understood as the angular frequency of rotation of its rotor, which is given on the nameplate (on the nameplate of the motor) as the number of revolutions per minute. A three-phase motor can be powered from a single-phase network, for this it is enough to add a capacitor parallel to one or two of its windings, depending on the mains voltage, but the motor design will not change from this.

The speed of rotation of an induction motor is usually understood as the angular frequency of rotation of its rotor, which is given on the nameplate (on the nameplate of the motor) as the number of revolutions per minute. A three-phase motor can be powered from a single-phase network, for this it is enough to add a capacitor parallel to one or two of its windings, depending on the mains voltage, but the motor design will not change from this.

So, if the rotor under load makes 2760 revolutions per minute, then the angular frequency of this engine will be 2760 * 2pi / 60 radians per second, that is, 289 rad / s, which is not convenient for perception, therefore they simply write “2760 rev / min. " As applied to an induction motor, these are revolutions taking into account slip s. The synchronous speed of this engine (excluding slip) will be equal to 3000 rpm, since when supplying stator windings with mains current...

Household electric motors and their use

Thanks to global electrification, our life has become more comfortable and cozy. The life of a modern person is impossible to imagine without electrical appliances. A lot of household appliances, which are entirely powered by electricity, are used today in every home. Even rural life is replete with various devices that make the economy more progressive and less burdensome for its owner.

Thanks to global electrification, our life has become more comfortable and cozy. The life of a modern person is impossible to imagine without electrical appliances. A lot of household appliances, which are entirely powered by electricity, are used today in every home. Even rural life is replete with various devices that make the economy more progressive and less burdensome for its owner.

In this article we will touch on the topic of household electric motors that faithfully serve in our vacuum cleaners, in washing machines, in coffee grinders, in food processors, in microwave ovens, and in many other household appliances, using which we don’t even think about how they are arranged, and how important the role of the electric motor is in them.Household electric motors are not many kilowatt industrial units, it is often the result of engineering to optimize common principles...

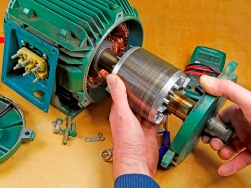

Collector electric motors differ from other types of motors by the presence of a collector-brush assembly. The assembly provides electrical connection of the rotor circuit with circuits located in the fixed part of the motor, and includes a collector (a set of contacts located directly on the rotor) and brushes (sliding contacts located outside the rotor and pressed against the collector).

Collector electric motors differ from other types of motors by the presence of a collector-brush assembly. The assembly provides electrical connection of the rotor circuit with circuits located in the fixed part of the motor, and includes a collector (a set of contacts located directly on the rotor) and brushes (sliding contacts located outside the rotor and pressed against the collector).

During the operation of the commutator motor in a power tool, sparking brushes can sometimes be observed. In some cases, this symptom leads to an early breakdown of the power tool, and in some it does not bode well. One way or another, it is useful in each case to understand what the cause of sparking is, in order to take the right measures in time if necessary. In this article, we will consider the causes of sparking brushes, as well as measures to combat the problems that cause this phenomenon.Intermittent mechanical brush contact ...

Causes of malfunctions of induction motors and methods for their elimination

Asynchronous electric motors are more common than others in production and are often found in everyday life. With their help, various machines are driven: turning, milling, grinding, lifting mechanisms, such as an elevator or crane, as well as various kinds of fans and hoods. This popularity is due to the low cost, simplicity and reliability of this type of drive. But it happens that a simple technique breaks down. In this article, we look at typical malfunctions of squirrel-cage induction motors.

Asynchronous electric motors are more common than others in production and are often found in everyday life. With their help, various machines are driven: turning, milling, grinding, lifting mechanisms, such as an elevator or crane, as well as various kinds of fans and hoods. This popularity is due to the low cost, simplicity and reliability of this type of drive. But it happens that a simple technique breaks down. In this article, we look at typical malfunctions of squirrel-cage induction motors.

Faults can be divided into three groups: the engine heats up, the shaft does not rotate or does not rotate normally, it makes noise, vibrates. In this case, the engine housing can be completely heated or some separate place on it.And the motor shaft may not budge at all, not develop normal speed, its bearing may overheatand, make abnormal sounds for his work, vibrate ...

How to distinguish an induction motor from a DC motor

Asynchronous motors are motors in the process of which under load a phenomenon of sliding is observed, that is, a “lag” of the rotor rotation from the rotation of the stator magnetic field. In other words, the rotor rotates not synchronously with the rotation of the stator magnetization, but asynchronously with respect to this movement. That is why these types of motors are called asynchronous (non-synchronous) motors.

Asynchronous motors are motors in the process of which under load a phenomenon of sliding is observed, that is, a “lag” of the rotor rotation from the rotation of the stator magnetic field. In other words, the rotor rotates not synchronously with the rotation of the stator magnetization, but asynchronously with respect to this movement. That is why these types of motors are called asynchronous (non-synchronous) motors.

In most cases, pronouncing the phrase “asynchronous motor”, they mean the brushless AC motor. The slip value of an induction motor can be different depending on the load, as well as on the power parameters and the method of controlling the stator winding currents. If we are dealing with a conventional AC motor, like AIR712A, then with a synchronous frequency of rotation of the magnetic field of 3000 rpm, under conditions of nominal mechanical load ...

Arduino and stepper motor: fundamentals, schemes, connection and control

Stepper motors are used to control the position of something, or to rotate the working unit at a given speed and angle. Such features made it possible to use it in robotics, numerically controlled machines (CNC), and other automation systems. In this article, we will consider a number of issues related to the construction of stepper motors and how to control them using the Arduino microcontroller.

Stepper motors are used to control the position of something, or to rotate the working unit at a given speed and angle. Such features made it possible to use it in robotics, numerically controlled machines (CNC), and other automation systems. In this article, we will consider a number of issues related to the construction of stepper motors and how to control them using the Arduino microcontroller.

All electric motors used in practice operate due to electrodynamic phenomena and processes occurring in the magnetic fields of rotors and stators. As we have already mentioned, any engine consists of at least two parts - mobile (rotor) and motionless (stator). For its rotation, it is necessary that the magnetic field also rotates. The rotor field rotates after the stator field. In principle, such basic information is enough to understand the general picture of the operation of electric motors ...