Categories: Repair of household appliances, Electric motors and their application

Number of views: 74086

Comments on the article: 0

Why spark brush motor

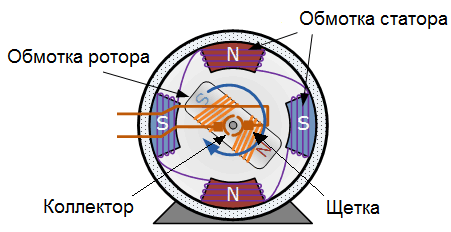

Collector electric motors differ from other types of motors by the presence of a collector-brush assembly. The assembly provides electrical connection of the rotor circuit with the circuits located in the fixed part of the motor, and includes a collector (a set of contacts located directly on the rotor) and brushes (sliding contacts located outside the rotor and pressed against the collector).

During the operation of the commutator motor in a power tool, sparking brushes can sometimes be observed. In some cases, this symptom leads to an early breakdown of the power tool, and in some it does not bode well. One way or another, it is useful in each case to understand what the cause of sparking is, in order to take the right measures in time if necessary. In this article, we will consider the causes of sparking brushes, as well as measures to combat the problems that cause this phenomenon.

Root cause

It is obvious that the intermittent mechanical contact of the brushes with the collector cannot but lead to sparking, because in fact, many times per second, the rotor electric circuit breaks and closes again.

The rotor contains a winding, which is a load mainly of an inductive nature. The breaking of such a chain is inevitably accompanied by a transition process, which is associated with the appearance of small arcs from self-induction of the rotor winding or the rotor and stator windings. Of course, the brushes wear out over time, as do the collector plates, but sometimes problems arise even before wear.

In fairness, we note that for the reason mentioned above, even a working collector engine cannot work without sparks at all, there is always a slight spark on the collector. A fully serviceable device normally reaches full power, develops working revolutions and sparks a little anyway. Another thing, if the spark is strong, there is a reasonable concern.

Sparking brushes as a sign of wear

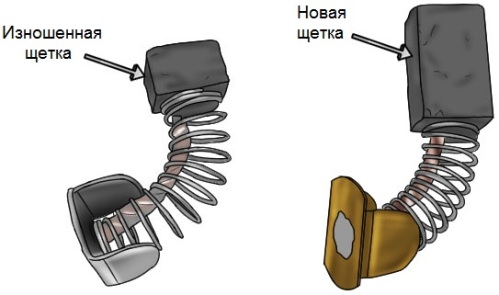

If the brushes are already very worn out, simply due to the age of the engine, then the engine will not be able to reach full speed and reach full power. In this case, the sparking will be very strong, and the engine will not start the first time.

How to verify that this is so? If the worn brushes are pressed with a screwdriver to the collector, the contact will become tight and the engine will start working. But it is worth loosening the clamp, as sparks reappear - the distance between the plates and brushes will be filled with small arcs. The brushes are clearly worn out - they should be replaced with new ones. Sometimes replacement is possible only together with brush holders and springs.

Perhaps a short circuit has occurred in the rotor winding

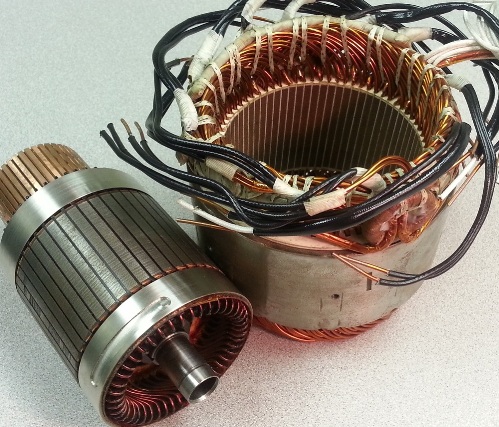

The winding of the anchor (rotor) of the collector motor traditionally contains several sections. If at least one is damaged, if there is an interturn circuit, then more current will be supplied to one section than to the others. This will lead to overheating of the winding in one place, and to uneven sparking on the collector - at individual junctions on the plates the sparks will be stronger than on others. It requires rewinding the anchor or a whole new anchor.

Is the stator winding OK?

A similar malfunction is possible inside the stator, when part of the winding overheats, and strong sparking is observed near one of the brushes. Check the resistance of both halves of the stator winding, they should be the same. If one of the parts of the stator winding has a resistance much less than the other, then rewinding or replacement of the stator is required.

See also: How to check the status of the winding of an electric motor

A dirty collector is the cause of an unnecessary short circuit on it, as a result extra sparks appear

Dust on the collector is formed as a result of gradual wear of the brushes - this is graphite dust. It accumulates between the plates (lamellas) of the collector, and creates “unauthorized” faults. Sparks appear due to short circuits. Just clean the collector with sandpaper, remove dirt between the lamellas.

Be sure to check how the brushes are located, if one of them is offset from the normal position, adjust the brushes if necessary. When the brushes are crooked, graphite dust is produced in an excessively large amount than with the correct arrangement of the brushes.

Another cause of contamination is carbon deposits on the collector due to overheating. When all other causes of sparking have been eliminated, it is necessary to clean the contacts from soot to improve the contact of the brushes with them.

If the contact is good, the resistance does not increase beyond the nominal, and there are no extra sparks. It is possible to clean the soot like graphite dust - with sandpaper, only rotating the rotor while the collector is clamped in special blocks.

See also at i.electricianexp.com

: