Categories: Electrician Secrets, Electric motors and their application

Number of views: 50067

Comments on the article: 2

How to determine the rotation speed of an electric motor

The speed of rotation of an induction motor is usually understood as the angular frequency of rotation of its rotor, which is given on the nameplate (on the nameplate of the motor) as the number of revolutions per minute. A three-phase motor can be powered from a single-phase network, for this just add a capacitor parallel to one or two of its windings, depending on the mains voltage, but the motor design will not change from this.

So, if the rotor under load makes 2760 rpm, then angular frequency of this engine It will be equal to 2760 * 2pi / 60 radians per second, that is, 289 rad / s, which is not convenient for perception, therefore they simply write “2760 rpm” on the plate. As applied to an induction motor, these are revolutions taking into account slip s.

The synchronous speed of this motor (excluding slip) will be 3000 rpm, because when the stator windings are supplied with a network current with a frequency of 50 Hz, each second the magnetic flux will make 50 complete cyclic changes, and 50 * 60 = 3000, and it turns out 3000 rpm - the synchronous speed of an induction motor.

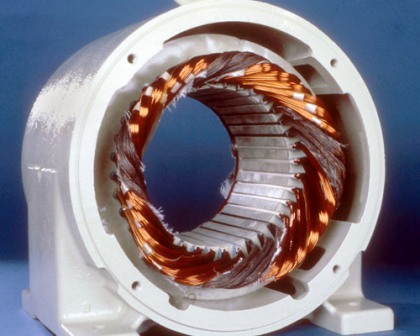

In the framework of this article, we will talk about how to determine the synchronous rotation speed of an unknown three-phase asynchronous motor by simply looking at its stator. By the appearance of the stator, by the location of the windings, by the number of grooves - you can easily determine the synchronous speed of the electric motor if you do not have a tachometer at hand. So, let's start in order and analyze this question with examples.

3000 rpm

About asynchronous electric motors (see - Types of electric motors) it is customary to say that a particular motor has one, two, three or four pairs of poles. The minimum is one pair of poles, that is, the minimum is two poles. Take a look at the drawing. Here you can see that two staggered coils for each phase are stacked in the stator - in each pair of coils one is located opposite the other. These coils form a pair of poles on the stator.

One phase is shown for clarity in red, the second in green, and the third in black. The windings of all three phases are arranged identically. Since these three windings are fed in turn (three-phase current), then for 1 oscillation of 50 in each phase, the stator magnetic flux will once turn around 360 degrees, that is, it will make one revolution in 1/50 second, which means 50 turns will be give me a sec. So it turns out 3000 rpm.

Thus, it becomes clear that to determine the synchronous speed of an induction motor, it is enough to determine the number of pairs of its poles, which is easy to do by removing the cover and looking at the stator.

Divide the total number of stator grooves by the number of grooves per one section of the winding of one of the phases. If you get 2, then you have an engine with two poles - with one pair of poles. Therefore, the synchronous frequency is 3000 rpm or approximately 2910, taking into account the slip. In the simplest case, there are 12 grooves, 6 grooves per coil, and 6 such coils — two for each of the three phases.

Please note that the number of coils in one group for one pair of poles may not necessarily be 1, but also 2 and 3, however, as an example, we considered the option of single groups per pair of coils (we will not focus on winding methods in this article).

1500 rpm

To obtain a synchronous speed of 1,500 rpm, the number of stator poles is doubled, so that for 1 oscillation of 50 the magnetic flux would make only half a revolution - 180 degrees.

For this, 4 winding sections are made for each phase.Thus, if one coil occupies a quarter of all the grooves, then you have an engine with two pairs of poles formed by four coils per phase.

For example, 6 grooves out of 24 are occupied by one coil or 12 out of 48, which means that you have an engine with a synchronous frequency of 1,500 rpm, or taking into account a slip of about 1350 rpm. In the above photo, each section of the winding is made in the form of a double coil group.

1000 rpm

As you already understood, in order to obtain a synchronous frequency of 1000 revolutions per minute, each phase forms three pairs of poles so that in one oscillation of 50 (hertz) the magnetic flux would turn only 120 degrees and rotate the rotor accordingly.

Thus, at least 18 coils are installed on the stator, with each coil occupying a sixth of all the grooves (six coils per phase — three pairs). For example, if there are 24 grooves, then one coil will occupy 4 of them. It will turn out a frequency taking into account a slip of about 935 revolutions per minute.

750 rpm

To obtain a synchronous speed of 750 rpm, it is necessary that the three phases form four pairs of moving poles on the stator, these are 8 coils per phase - one opposite the other - 8 poles. If, for example, there are 48 grooves per coil for every 6 grooves, you have an asynchronous motor with synchronous speeds of 750 (or about 730, taking into account sliding).

500 rpm

Finally, to obtain an induction motor with a synchronous speed of 500 revolutions per minute, 6 pairs of poles are needed - 12 coils (poles) per phase, so that for each oscillation of the network the magnetic flux rotates 60 degrees. That is, if, for example, the stator has 36 grooves, while the coil has 4 grooves, you have a three-phase motor at 500 rpm (480, taking into account slip).

See also:How to distinguish an induction motor from a DC motor

See also at i.electricianexp.com

: