Categories: How does it work, Electric motors and their application

Number of views: 18178

Comments on the article: 0

Types of electric motors and the principles of their work

Imagine what the modern world would be like if all electric motors suddenly disappeared from it. Suppose we would replace them with heat engines. But heat engines are bulky, emit steam and exhaust gases, while electric motors of comparable power are compact, fit perfectly on machines, electric vehicles, and other equipment, while being environmentally friendly, economical, and reliable. It is impossible to imagine the modern world without electric motors, greatly facilitating the work of people, in short, making our life more comfortable.

Thanks to electric motors, we get mechanical energy from electrical energy. And weight and size characteristics, power and the number of revolutions per minute are of decisive importance in this process, which in turn are associated both with the design features of the engines and with the parameters of the supply voltage.

By the type of supply voltage, electric motors are: AC or DC. By the control method: step, linear, servo (servo). AC motors, in turn, are asynchronous and synchronous. Let's look at the types of electric motors, note their features, and talk about the principles of operation of each of them.

DC motors

To build electric drives with high dynamic characteristics, DC motors are used. They are characterized by high overload capacity and uniform rotation. It is DC motors that are often used in electric vehicles. They are equipped with many machine tools, machines, units, including household appliances.

The operation of the classic DC motor is based on the rotation of the frame with current in an external magnetic field: current is supplied to the frame through the brush-collector assembly, and the stator magnetic field is obtained either from permanent magnets or from the same direct current (magnetic field of the coil with current) . As a result, the current frame rotates in a magnetic field. Instead of the frame, a coil with a current on the magnetic circuit - a rotor can protrude.

AC motors

AC motors are very widely used in everyday life and in industry, as they are considered more universal in comparison with DC motors. AC motors have a simple design, are more reliable than DC motors, and are unpretentious in handling.

For example, most home fans and industrial hoods are equipped with asynchronous AC motors. They are equipped with winches, pumps, machine tools. The simplicity of industrial frequency AC motors is the lack of a brush-collector assembly and complex electronics.

Stepper motors

Stepper motors operate by converting discrete DC electrical pulses into mechanical movements (steps). Office equipment, machine tools, robots - wherever high speed and uniformity of movement of the working body are required, step-by-step electric motors are used today. To control the speed of rotation of the rotor, the electronic unit controls the pulse repetition rate and their duty cycle. A stepper motor is a synchronous brushless DC motor.

Servos (Servomotors)

Servo drive (servo drive) is a high-tech DC motor. Unlike a stepper motor, the servo motor also has a rotor position sensor in the design, with the help of which a negative feedback mechanism is implemented.

Motors of this type are capable of developing high revolutions and power, like stepper DC motors, but the adjustment of the position of the working body is more accurate. For CNC machines, a servo drive is just what you need. Many modern industrial machines are equipped with servo drives that are integrated into a high-precision computer control system.

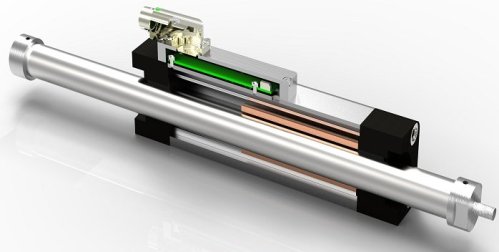

Linear electric motors

Instead of a rotor, a linear DC motor has a rod (rod) with magnets that is linearly moved through the stator relative to the inductor. Engines of this type are gaining popularity as drives of mechanisms with reciprocating movements during operation.

This is a reliable and economical solution, eliminating the need to use any kind of mechanical transmission. Pulses of the required polarity and duration are sent to the coil, forming a magnetic field of the desired configuration, which, for its part, acts on the rod, and the current position of the rod is monitored thanks to Hall sensors built into the stator.

Synchronous motors

Saying “synchronous motor”, they traditionally mean an alternating current motor, in which the rotational speed (or angular velocity) of the rotor is equal to the angular velocity of the magnetic flux in the stator cavity. Most often we are talking about engines whose rotors carry permanent magnets or an excitation winding, creating a strong intrinsic magnetic field that prevents slipping.

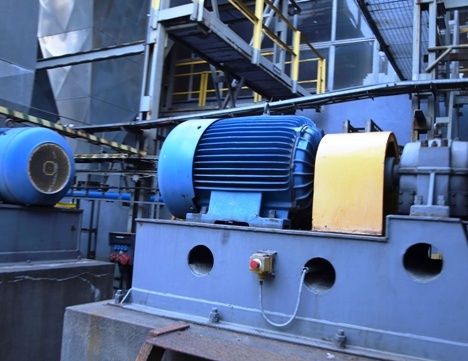

In synchronous motors, the rotor speed is therefore constant. Powerful fans, cranes, pumps, - in many applications where high power and constant speed are required, regardless of load, synchronous motors are used.

Induction motors

Most often, an asynchronous motor is called an AC motor, in which the frequency (or angular velocity) of the rotor rotation differs from the angular velocity of the stator magnetic flux. That is, in such an engine there is a "slip". Asynchronous AC motors come with a squirrel-cage (like "squirrel cage") rotor or rotary rotor.

More powerful asynchronous motors are made with a phase rotor, the magnitude of the magnetic flux at such a rotor is regulated by a rheostat, and the rotation speed is adjustable. Less critical (to the dependence of the rotor speed on the load) equipment is equipped with asynchronous motors with a squirrel-cage rotor.

See also on our website: Types of electric generators and the principles of their work

See also at i.electricianexp.com

: