Categories: Electrician Secrets, About electricians and not only

Number of views: 9684

Comments on the article: 0

Current clamp application examples

To diagnose malfunctions in electrical equipment or electrical installations, it is often necessary to measure currents. There are two options: use an ammeter or using current clamps. The first option can be done using a conventional multimeter, but it is bad in that you need to break the circuit, and this is not always possible and not always convenient for correct measurements. The second method, clamp meters, allows you to find out the current in the circuit without disconnecting it.

The principle of operation of current clamps is based on the phenomenon of electromagnetic induction. The conductor, in which the current is measured, is inserted into the magnet wire, on which the secondary winding is wound. The measured current in this case is called primary, and the current in the measuring coil (secondary winding) is called secondary. Moreover, its value is proportional to the primary current and can be calculated.

Earlier, clamp meters, for the most part, could measure only alternating current, since the EMF on the winding can occur only under the condition of an alternating magnetic flux created by alternating electric current. Most modern, even the cheapest models, are capable of measuring both direct and alternating currents. DC measurement is made possible by the use of a Hall sensor.

In more detail, the device, the principle of operation, as well as general approaches to measuring current clamps were considered on the site earlier -How to use current measuring clamps. In the same article, we will consider several examples from real life and share a number of useful points that not everyone knows and uses.

Measurement technology

To determine the current in the circuit, you must enter into the solution of the magnetic circuit ONE conductor core or conductive bus. To open the magnetic circuit, squeeze the lever at the end of the pliers.

After introducing the conductor, release the lever and the magnetic circuit will close. On the measuring device, the appropriate measurement limit and mode must be selected, for alternating current it is denoted as "I ~", and for constant "I =".

Question: "Why can not clamps measure current in several wires or on a cable with phase and zero?"

When a current flows through a conductor, a magnetic field is formed around it, which means that the magnetic fluxes of several adjacent conductors are added up, forming the resulting flux. Therefore, it is impossible to measure several wires in which different currents flow or the same current in different directions. This is clearly illustrated in the figure below.

That is, to measure the consumption currents of a device that is connected to an AC network with one or more phases, the current is measured only in the core of a particular phase. If the network is single-phase, then measurements can be carried out on a phase or neutral conductor, but not together. The same goes for measuring current with clamps in a DC network.

IMPORTANT:

When measuring with ticks, the conductor or group of conductors that belong to one pole (phase) is captured and feed one consumer or one measured group!

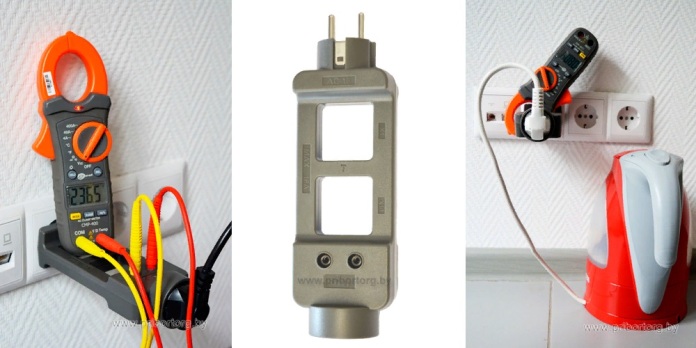

This requirement causes some inconvenience when measuring the currents of most consumers, both single-phase and three-phase. For example, to measure the power of the iron you need to open the cable, and separate the cores. Therefore, electricians use special adapters. In essence, such an adapter is a small extension cord from a plug and one socket connected either by separate cores from a wire, or type PV3 wires or others. Or a special device, as in the figure below, is the AC-16 adapter.

Measurement Examples

Let's look at a few typical examples when you need to measure current for diagnosing electrical circuits and consider a little trick.

Case One. You noticed that you began to pay more for electricity, while the mode of operation of electrical equipment remained the same. An unauthorized connection to your network is possible. If the counter you can’t determine accurately, use the ticks.

To do this, in the electrical panel of an apartment or house you need to find a convenient place to take measurements, you need to find a separate phase or neutral conductorif you are lucky - you can get a tick in the place of connection of the circuit breaker. Turn off all consumers in your home and measure the current, if you see a number other than zero on its display - you should look for an unauthorized connection.

Case Two. You have a three-phase electric motor, which began to warm more than before. There are two main reasons for increased heat. The first does not apply to electricity when the bearings are worn out - they will heat up more and give off heat to the metal casing. The second reason is interturn circuit or leakage to the case. In this case, it is possible to get ahead of the malfunction by comparing the currents in phases.

In the normal case, the currents in all three phases will be equal, and in the neutral wire (if any) there will be no current. If you do this with an ammeter, you will have to disconnect the core from the electric motor each time you disconnect, for which you will have to stop and start it each time. This of course will not give reliable measurement results.

Interesting:

In some electrical installations, it is possible to measure currents and create circuit breaks after bypassing the disconnector with an ammeter, but this is rare.

In this case, it is most convenient to measure the phase currents with ticks, literally for three movements of the hand you will determine quite accurately serviceability of the electric motor.

Case Three. You notice that your car’s battery is running out faster. If you have not installed additional devices that are directly connected to the battery, such as car radios (although this is not a correct connection, such devices are connected in the active circuit after the ignition is turned on) - then there is a leak somewhere.

For this, the ammeter is installed in the gap of the positive battery wire. But such a measurement is not always convenient, and if you need to measure currents before turning on the engine and after, it is impossible, because your ammeter is likely to fail from the currents of the starter. Conveniently use measuring pincers to search for leaks. After installing the clamps on the positive battery wire, the fuses are removed one by one from the fuse box, disconnecting possible consumers, until they find a circuit with a current leak.

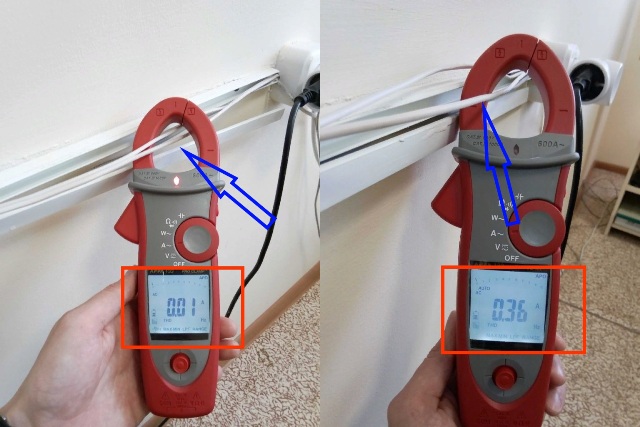

Question: "If the leakage current or other measured current is low and the clamps do not determine it, then how to measure with their help?"

To measure small currents with current clamps, you need to wrap the wire several times around the magnetic circuit. The value that appears on the display of the measuring device is divided by the number of turns of wire. As was said, the magnetic fluxes add up, and the resulting flux will be equal to the sum of each of them. Therefore, the readings of the ticks will exceed the actual current in an amount multiple to the number of turns of the wire.

Important: Be careful, because not every measuring clamp supports DC measurement.

Safety precautions

It is important that clamp measurements do not cause a short circuit or electric shock in the circuits. For this, the magnetic core of the ticks is covered with a dielectric sheath. Thus, in the event of accidental contact with the ticks of two adjacent conductive parts, a short circuit will not occur. But note that the measuring device must be dry.

Measurements in circuits up to 1000V, for example, 380 / 220V should be carried out with dielectric gloves, and a dig should be laid under your feet or dielectric bots should be worn on your feet. This is necessary to avoid the consequences of accidental contact with live parts.

See also at i.electricianexp.com

: