Categories: Featured Articles » Electrician Secrets

Number of views: 59324

Comments on the article: 0

How to connect the motor from the washing machine to the 220 V power network

A home foreman in the household often has to do something that manually is not always easy and convenient. In this case, a variety of machines come to the rescue. But you need a device that will drive them, for example, an electric motor. But asynchronous three-phase motors, although simple in design and very common, it is not always possible to find and buy capacitors for it. Therefore you can use engines from household appliances. In this article, we will consider the scheme of connecting the motor from the washing machine to the network for direct rotation and reverse.

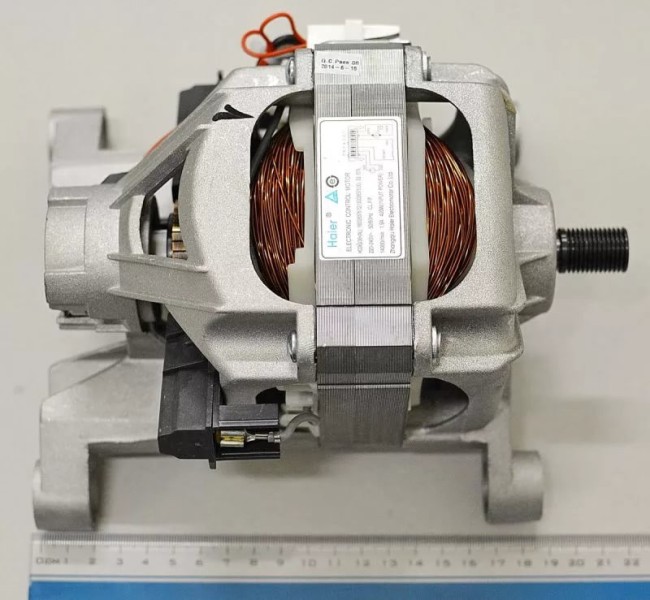

What engines are used in washing machines

Most washing machines use commutator motors. They are convenient in that they do not require starting and working capacitors, can be directly connected to the network. In addition, the simplest speed control for them can be bought at any electrical goods store.

The collector motor from the washing machine consists of:

-

Stator;

-

Rotor with manifold;

-

Brush assembly;

-

Tacho generator or hall sensor.

To measure engine speed and their regulation, tachogenerators or hall sensors are used. They are not used for ordinary starting from the engine from the 220V network, but they are needed to work with complex speed controllers that maintain the power on the shaft regardless of its load (within the rated range, of course).

Wiring diagram

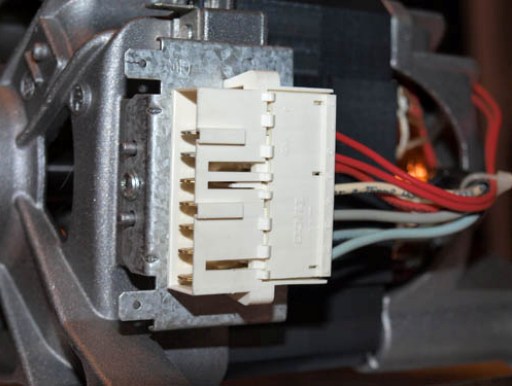

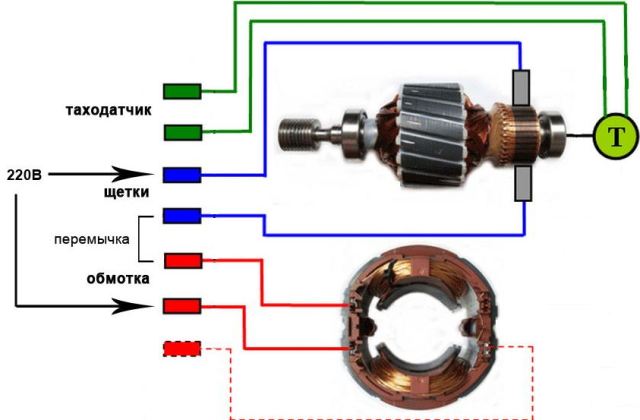

Initially, the motors from the washing machine are connected to the network using a terminal block. If it has not been removed before you, when inspecting the engine you will see a similar picture:

The order of the wires may vary, but basically their purpose is:

-

2 wires from brushes;

-

2 or 3 wires from the stator winding.

-

2 wires from the speed sensor.

Note:

If you have three wires from the stator, then one of them is the average output, used to increase revolutions in spin mode. Then if you poking winding found that one pair of wires gives resistance higher than the other pair, then by connecting to the ends with high resistance the speed will be lower, but the torque is higher. And if you choose conclusions with lower resistance, then vice versa - the rpm is higher, and the moment is lower.

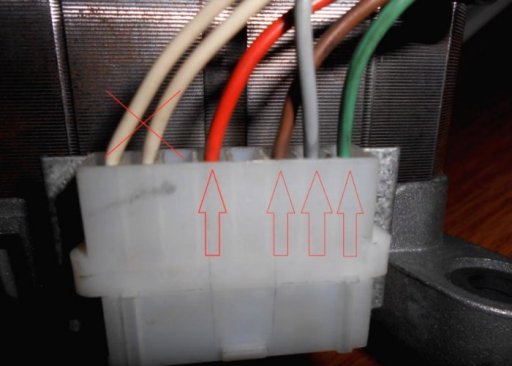

Depending on the specific model, contacts of some kind of protection, for example, thermal and so on, can be displayed on the block. As a result, to simply connect to the network, we need four wires, for example, these:

Recall that adding most engines washing machines - These are sequential excitation collector motors. What does it mean? It is necessary to connect the stator winding in series with the field winding, that is, with the armature winding.

To do this, you need to connect one end of the stator winding to the network wire, connect the second end of the stator winding to the wire of one of the brushes, and connect the second brush to the second network wire, this connection diagram is shown in the figure below.

Reverse

In practice, it happens that for use in the wall it is impossible to fix the engine in another plane, then its rotation direction may not suit you. There is no need to despair. To change the direction of rotation of the motor from the washing machine, you just need to swap the ends of the stator winding and the field winding.

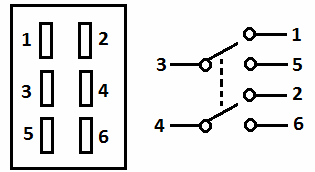

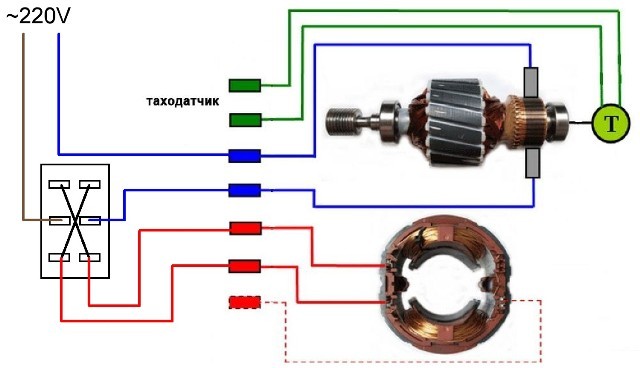

In order to be able to switch the direction of rotation of the engine during operation, you need to use a DPDT type tumbler. These are six contact toggle switches in which there are two independent contact groups (two poles) and two positions in which the middle contact connects to either one or the other extreme contact.Its internal circuit is depicted above.

The connection diagram of the engine from the washing machine with the ability to switch the direction of rotation is shown below.

You need to solder the wires from the brushes to the extreme contacts of the toggle switch, and to one of the middle contacts the wire from the stator winding, to the second - the network wire. The second end of the stator winding is still connected to the network. After that, you need to solder the jumpers to the free two cross-wise contacts.

Speed adjustment

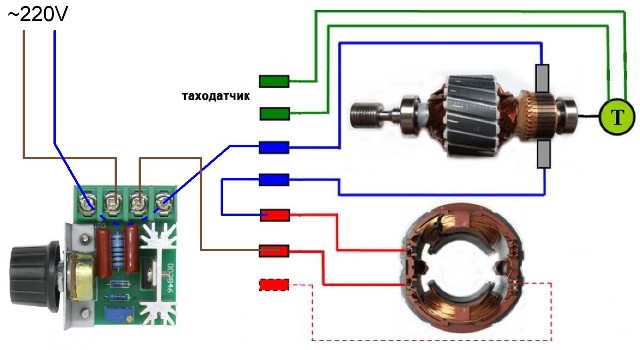

The revs of all the collector motors are easily adjustable. To do this, change the current through their windings. This can be done by changing the supply voltage, for example, cutting off part of the phase, reducing the effective voltage value. This adjustment method is called the Pulse Phase Control System (SIFU).

In practice, you can use any household dimmer power 2.5-3 kW. You can use a dimmer for lighting lamps, but in this case, replace the triac with BT138X-600 or BTA20-600BW, for example, or any other with a 10-fold current margin relative to motor consumption, unless of course the initial characteristics are enough. You see the connection diagram below.

But for the simplicity of the solution you have to pay. Since we reduce the supply voltage, we limit the current. Accordingly, the power decreases. However, under load, the engine begins to consume more current in order to maintain the desired speed. As a result, due to the reduced voltage, the engine will not be able to develop maximum power, and its speed under load will drop.

To avoid this, there are special boards that maintain the given speed while receiving feedback from the speed sensor. It is those wires that we did not use in the circuits considered. This works according to an algorithm similar to this:

1. Checking the set speed.

2. Reading sensor values and storing them in a register.

3. Comparison of the sensor readings, real revs with the given ones.

4. If the actual speed corresponds to the set - do nothing. If the revs do not match then:

-

If the revolutions are increased - increase the angle of cut of the SIFU phase by a certain value (lower voltage, current and power);

-

If the revolutions are lowered, we decrease the angle of cut of the SIFU phase (we increase the voltage, current, and power).

And so it repeats in a circle. Thus, when you load the motor shaft - the system itself decides to increase the voltage supplied to the motor or reduce it when the load increases.

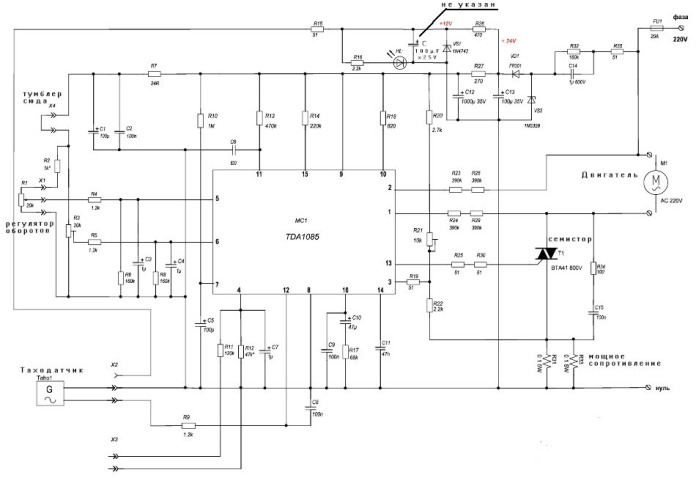

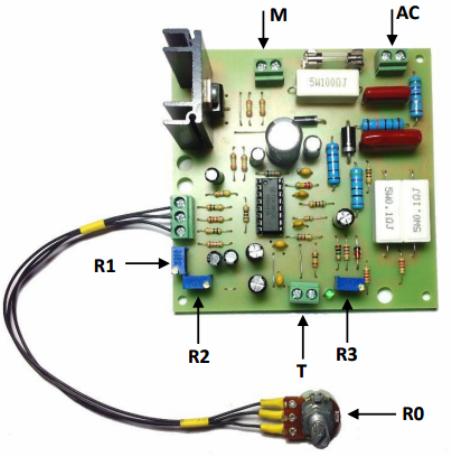

It’s not necessary to rush to develop such microcontroller devicesThere are inexpensive turnkey solutions. An example of such a device are built on integrated circuit TDA1085. An example of the connection diagram you see below.

Signatures here indicate:

-

M - exit to the engine.

-

AC - network connection.

-

T - connection to the tachometer.

-

R0 - current speed controller.

-

R1 - minimum speed.

-

R2 - maximum speed

-

R3 - to fine-tune the circuit if the engine runs unevenly.

You can find more detailed instructions here - https://i.electricianexp.com/en/regulyator-oborotov-tda-instruktsiya.pdf

Scheme of the given board (click on the picture to enlarge):

Conclusion

Note that the collector, or as it is also popularly called, the brush motor from washing machines is quite high-speed, in the region of 10,000-15,000 rpm. This is due to its design. If you need to reach low revs, for example, 600 rpm, use a belt or gear drive. Otherwise, even with the use of a special controller, you will not be able to achieve normal operation.

See also at i.electricianexp.com

: