Categories: Featured Articles » Novice electricians

Number of views: 169

Comments on the article: 0

What is electrical resistance and how does it depend on temperature

From the point of view of the electromagnetic process occurring in it, any element or section of an electric circuit is primarily characterized by the ability to conduct current or impede the passage of current. This property of circuit elements is evaluated by their electrical conductivity or the value of reverse conductivity - electrical resistance.

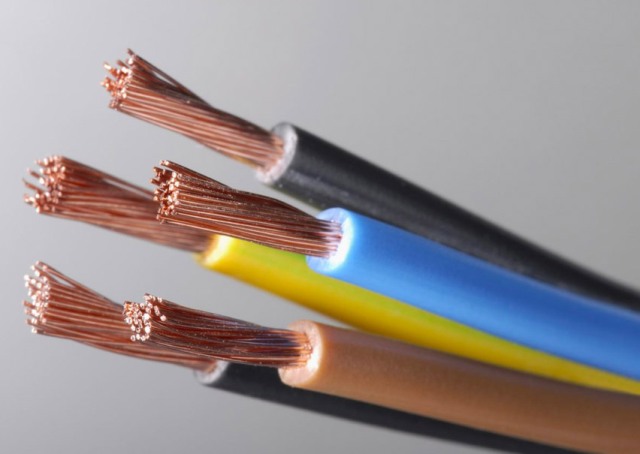

Most electrical devices consist of conductive parts made of metal conductors, usually provided with an insulating coating or sheath. The electrical resistance of a conductor depends on its geometrical dimensions and material properties. The value of electrical resistance is equal to

R = ρl / s = l / (γs)

Where l - conductor length, m; s — cross-sectional area of the conductor, mm2; ρ — conductivity, ohm·mm2/m; γ — specific conductivity, m / ohm·mm

Electrical resistivity

The resistivity and conductivity take into account the properties of the material of the conductor and give the values of resistance and conductivity of the conductor with a length of 1 m and a cross-sectional area of 1 mm2.

In terms of resistivity ρ All materials can be divided into three groups:

-

conductors - metals and their alloys (ρ 0.015 to 1.2 ohm·mm2/m);

-

electrolytes and semiconductors (ρ from 102 up to 206 om·mm2/m);

-

dielectrics, or insulators (ρ from 1010 up to 2011 om·mm2/m).

In electrical devices, materials with both small and high resistivities are used. If it is required that the circuit element has a slight resistance (for example, connecting wires), it should be made of conductors with a low value ρ - of the order of 0.015-0.03, for example of copper, silver, aluminum.

Other devices, on the contrary, should have significant resistances (electric incandescent lamps, heating devices, etc.), therefore, their current-carrying elements should be made of materials with high resistivity ρ, usually representing metal alloys. These include, for example, manganin, constantan, nichrome, which matter ρ from 0.1 to 1.2.

Temperature dependence of electrical resistance

The value of electrical resistance also depends on the temperature of the conductor, which may vary due to heating of the conductor by electric current or due to changes in the temperature of the environment. When the temperature of the conductor changes, its resistivity changes. The above p values for some materials are valid at temperature

The independence of resistance from temperature is approximately expressed as follows:

Rto = R20about·[1+α·(to-20°)]

Rto - resistance of the conductor at temperature to, R20about- the same at a temperature of 20 ° C, ohm; α Is the temperature coefficient of electrical resistance, showing the relative change in the resistance of the wire when it is heated by 1 ° C.

From this expression, the quantity α is equal to

α = (Rto - R20about) / (R20about·(to-20°))

For most metals and their alloys, the value α > 0, i.e., when heated, their resistance increases and vice versa.

For pure metal wiring, the values of a range from 0.0037 to 0.0065 per 1 ° C. For high resistance alloys α has very small values, tens and hundreds of times smaller than that of pure metal conductors. So for example, for manganin α = 0.000015 at ° C.

Values α for semiconductors, electrolytes are negative, of the order of 0.02. The temperature coefficient of electrical resistance is also negative and in its absolute value is ten times higher than α for metals.

The dependence of resistance on temperature is widely used in technology for measuring temperatures using the so-calledresistance thermometers, whichαshould be big. In a number of devices, on the contrary, materials with a low value are usedα in order to exclude the influence of temperature fluctuations on the readings of these devices.

An example of calculating the change in the resistance of a conductor when heated: How to calculate the filament temperature of a filament lamp in nominal mode

AC Resistance

The resistance of the same conductor for alternating current will be greater than for direct current. This is due to the phenomenon of the so-called surface effectwhich consists in the fact that alternating current is displaced from the Central part of the conductor to the peripheral layers. As a result, the current density in the inner layers will be less than in the outer ones.

Thus, with alternating current, the cross section of the conductor is used, as it were, incompletely. However, at a frequency of 50 Hz, the difference in resistance to direct and alternating currents is insignificant and can be neglected in practice.

DC conductor resistance is calledohmic, and alternating current -active resistance. Ohmic and active resistances depend on the material (internal structure), geometric dimensions and temperature of the conductor. In addition, in coils with a steel core, the value of the active resistance is affected by the loss in steel.

Active resistances include electric incandescent lamps, electric resistance furnaces, various heating devices, rheostats and wires, where electrical energy is almost completely converted into heat.

In addition to active resistance, in alternating current circuits there are inductive and capacitive resistances (see -What is inductive and capacitive load?).

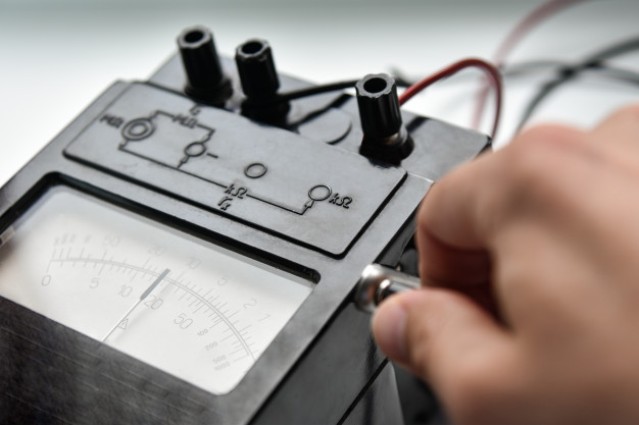

Insulation resistance

The reliability of the electrical network and equipment to a large extent depends on the quality of insulation between live parts of different phases, as well as between live parts and ground.

The quality of insulation is characterized by the magnitude of its resistance. The definition of this value is usually limited during the control tests of networks and installations with a voltage of less than 1000 V. For installations of higher voltage, the electric strength and dielectric losses are additionally determined.

Depending on the state of the network (the network with the power receivers turned off or on, whether or not under voltage), various switching circuits for measuring devices and methods for calculating the value of insulation resistance are used. The most widely used megaohmmeters and voltmeters for this purpose.

The task of determining the insulation resistance is specific and extensive in volume, therefore, to study it, we recommend that you refer to this article:How to use a megaohmmeter

What is the calculation of wires for heating for?

Electrical resistance affects for heating wires and cables. The wires connecting the energy source to the receivers should provide power to the receivers with a small loss of voltage and energy, but at the same time they should not be heated by the current passing through them above the permissible temperature.

Exceeding the permissible temperature values leads to damage to the insulation of the wires and, as a consequence of this, to a short circuit, i.e., a sharp increase in the current value in the circuit. Therefore, the calculation of the wires allows you to determine the cross-sectional area at which the voltage loss and heating of the wires will be within normal limits.

Typically, the cross-section of wires and cables for heating is checked according to the tables of permissible current loads from PUE. If the cross section does not fit the heating conditions, you should choose a larger cross section that meets these requirements.

Resistance heating units

The main elements of electric furnaces are electric heating elements and a thermal insulation device that prevents heat loss to the surrounding space. Heat-resistant non-metallic materials with high resistivity (coal, graphite, carborundum) and metallic materials (nichrome, constantan, fechral, etc.) are used as materials for electric heating elements.

High resistivity materials ρ allows you to design heating elements with a large cross-sectional area and surface, and the choice of materials with a small coefficient of expansion α, provides immutability of the geometric dimensions of the element when heated.

Heating elements made of graphite-type materials are made in the form of rods with a tubular or solid section. Metal heating elements are made in the form of wire or tape.

Using fuses

To protect the wires of the electric circuit from currents exceeding the permissible values, applycircuit breakers andfuses various types. In principle, a fuse is a section of an electrical circuit with low thermal stability.

The fuse insert is usually made in the form of a short conductor of small cross section made of a material with good conductivity (copper, silver) or a conductor with a relatively high resistivity (lead, tin). If the current increases above the value for which the fuse is designed, the latter burns out and disconnects the part of the circuit protected by it or the current collector.

See also:Voltage, resistance, current and power are the main electrical quantities

See also at i.electricianexp.com

: