Categories: Featured Articles » Electrician at home

Number of views: 153610

Comments on the article: 9

Open wiring - popular wiring methods

Laying methods and materials used in open wiring.

There are two types of wiring - they are hidden and open. Usually, hidden wiring better open in terms of room design and energy performance, as wires under a layer of plaster are cooled better than in the open air and their routes and junction boxes do not interfere with the arrangement of furniture and equipment.

There are two types of wiring - they are hidden and open. Usually, hidden wiring better open in terms of room design and energy performance, as wires under a layer of plaster are cooled better than in the open air and their routes and junction boxes do not interfere with the arrangement of furniture and equipment.

However, in addition to the advantages, hidden wiring has its drawbacks. This is the need for wall shredding and their subsequent restoration, the complexity of the work performed, construction waste, the need to stop technological processes inside the premises, the complexity of subsequent diagnostics and modernization, etc. This is especially difficult wiring inside wooden buildingsOf course, if the recommendations of the PUE are followed.

Open wiring is often done inside buildings when changing ownership; it is much faster, cheaper, and you can easily add or remove segments in the future. In buildings and structures made of combustible materials, open wiring is the preferred and most common way of installing lighting and electrical networks.

There are several ways to lay open wiring. Let us consider each of them sequentially.

Laying open wiring with twisted wire on insulators

Historically, the very first way is laying with stranded wire suspended from the walls and ceiling on ceramic insulators. This type of wiring can be seen in the village houses of the beginning of the last century. But, oddly enough, now he is back in fashion (open wiring using twisted wires or, in another, retro style wiring)

Replicas of both old cars and old houses are being built. People want authenticity and a flag in their hands. But with the materials it’s quite difficult. It is very difficult to get ceramic insulators for open wiring. You can only advise, roll them up in abandoned houses or search among Made in China products.

Twisted wire will also have to be made manually. For this, multicore copper wires are suitable, preferably with double insulation and with a cross section of at least two and a half square millimeters. If you chose this method, know that the fashion comes and goes, and the wiring will remain with you ...

Bracket for open wiring

With other laying methods, it is better to use rigid single-core cables in double (VVG NG) or even triple (NYM) insulation with copper conductors. Wire cross section 2.5 square millimeters for sockets and 1.5 square millimeters for lighting. Such cables are fixed with electrical brackets directly to the surface, if the cross-section of the core does not exceed 6 millimeters square and the laying is carried out with one cable.

If you, for some reason, want to use a cheaper cable, for example PUNP, then it is necessary to install a non-combustible gasket under it. Usually it is metal or asbestos. The gasket is placed so that it protrudes 10 mm on each side of the cable. Another way is to provide an air gap of at least 10 mm from the combustible base. The latter method resembles installing a cable on ceramic insulators.

Experience has shown that it is better not to use asbestos in the manufacture of open wiring, as it is toxic material. If you use the correct cross-section for VVG NG or NYM for open wiring, then you can refuse gaskets. This method is the cheapest, but from the point of view of aesthetics is very controversial. This is especially striking in the passage of several parallel cables.

Corrugated Pipe Open Wiring

From an aesthetic point of view, this is the preferred method. Moreover, special corrugated electrical pipes do not support combustion and protect electrical cables mechanically. Pipes are fixed to the walls with special clips or plastic and metal ties. In one corrugation, you can tighten several cables at once, but at the same time, in case of modification of wiring, you will have to change all the cables stretched in this corrugation.

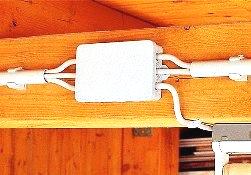

Corrugated pipe fits well on uneven walls of cylindrical logs and looks better than a separate cable. Such a pipe, in addition, provides an air gap between the wall and the cables of open wiring. A corrugated pipe option is a rigid HDPE pipe. It should be noted that if we are talking about open wiring in wooden houses, then when passing walls, you need to use metal bushings. They will protect wiring in case of wood shrinkage.

Open wiring in cable - channels and electrical boxes and baseboards

In this case, the cables are laid in pre-installed on the walls and ceiling plastic boxes. Cable - channels made of flame retardant plastic. It’s rather difficult to install the box, if the walls are not even, they emphasize this. It takes skill, dexterity and a good tool. The wires laid in the channels are closed with snap covers.

An important advantage of cable channels is the simple ability to upgrade wiring by laying additional wires in already laid channels. A large number of accessories are produced for cable channels: angles, tees, built-in sockets and boxes, etc. The presence of various accessories greatly facilitates installation.

Open wiring with this installation method is the most beautiful. In addition, acrylic paints and their shop tinting allows you to “mask” white cable channels on the background of multi-colored walls.

Electrical baseboards allow you to hide wiring for outlets. Due to their elasticity, such skirting boards hide the curvature of the walls. The disadvantage of plastic boxes when laying open wiring on wooden walls is the need to wait for the wood to dry. Since the warping of the tree can lead to the opening of the boxes and even their breakage and cracking.

Combining different ways

In real conditions, you have to combine different methods of open wiring. A cable - channels are laid on a more even wall, along corrugated uneven walls, and a plastic baseboard on the floor. In places where special strength is needed - a cable in a metal hose (metal corrugated pipe). When drawing up a wiring plan, you need to consider all the advantages and disadvantages of each method.

Now you know the basic ways to lay open wiring. The choice is always yours. Perhaps you suggest some new ways of open wiring. Practical experience is very valuable. Share it c site readers!

See also on this topic:Installation of open wiring in the home

See also at i.electricianexp.com

: