Categories: Electric installation work

Number of views: 4986

Comments on the article: 0

How to connect wires and cables of different sections

It happens that when you install electrical wiring, you have to connect wires of different sections. And there is, apparently, no problem, because there are many different ways to do this. Nevertheless, in each case, one of the options will be most successful. We can talk about mounting a junction box, while installing a wall outlet is a completely different matter, where good contact and possibly the smallest transition resistance at the fixation point are very important.

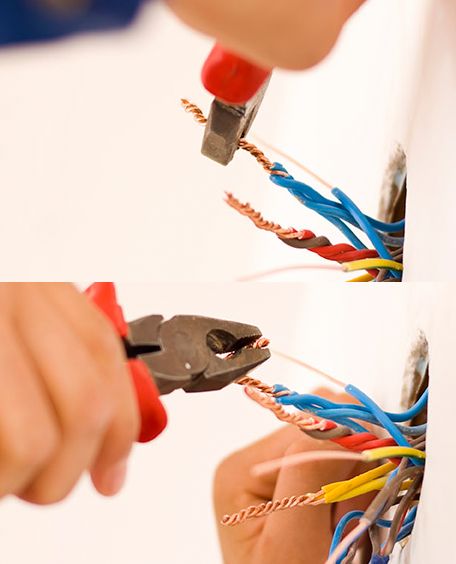

From ancient times to this day, ordinary twisting has not lost popularity. Using twisting, it is easy to connect wires of close sections, for example 1 sq. Mm and 1.5 sq. Mm. And if the sections are very different? Then a good twist will not work, because the cores will not be equally snug against each other.

In order for the twist to turn out to be high-quality, the wires should evenly wrap around each other, it should not be such that a thin wire is simply wound over a thick one, because then the contact will be bad and not reliable. Moreover, even the correct twisting must always be soldered or welded at the end, then the connection will turn out to be durable and reliable, one might say - for centuries.

More about twisting:Why wire twisting is prohibited andWhy welding is always better than other methods of connecting wires

A screw terminal clamp or terminal block is another time-tested way to connect wires of different sections. Rows of clamping screws are located on both sides of the block, so that wires of various sizes can be inserted on both sides of the block, so that each wire is clamped by an individual screw.

Wires close in cross section are well connected using such clamps, you only need to take into account the current load, and choose a block of the correct size, for the appropriate current, with a suitable diameter of the contact tubes and screws.

Typically, the maximum permissible continuous current is indicated directly on the screw terminal marking. The wire is cleaned of insulation to the length of half the terminal, inserted, fixed, clamped with a screw. The connection is ready.

Similar here: Wire Terminal Blocks

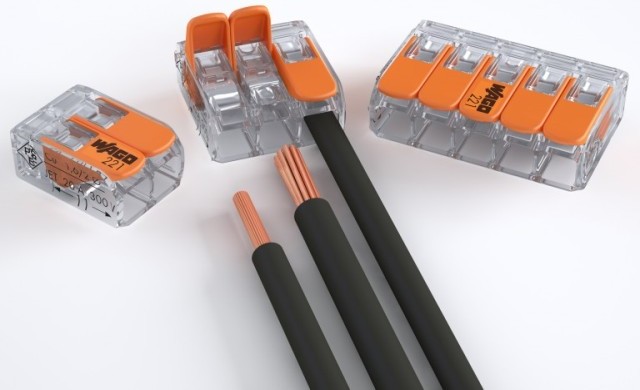

Especially for connecting wires of different cross-sections, convenient Wago self-clamping terminals have been created. The cores are stuck individually, each in an individual socket, after which the installer remains to press the lever, and the connection is ready.

In one hole, you can insert a wire with a cross section of 1 square mm, in another - 4 square mm, and such a connection, despite the difference in cross-sections by four times, will work for a long time and properly, simply by virtue of a competent terminal device. For different groups of sections, Wago terminals of various series are produced, each designed for its own maximum permissible continuous current.

About Wago terminal blocks (this is always a very hot topic for electricians):

Wago terminals: types, characteristics, how to choose and how to use it correctly

How to distinguish a good self-clamping terminal block from a fake

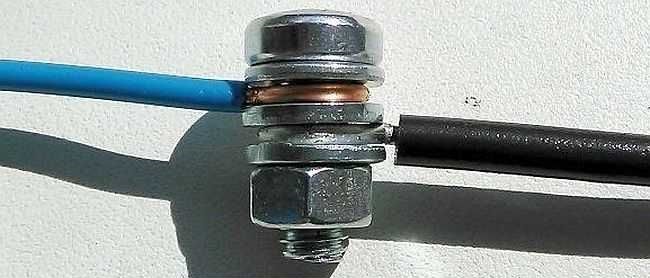

In the end, wires of different sections can be connected with a simple bolt with washers and nuts, and the connection will be very durable, reliable, and most importantly - the contact area of the wires will be fundamentally quite extensive.

To connect the wires in this way, it will be necessary to strip both wires to such a length that it is enough for one full revolution around the body of the bolt. At the ends of the cores of each of the connected wires (there may be more than two), rings are formed into a girth of the bolt.

The washer is first put on the bolt, then the ring (located on the end of the first wire) is put on the bolt, then another washer is intermediate, then the second ring (the second of the wires), then the washer again, etc.All this sandwich at the end is clamped with a nut.

A solution with a nut-type clamp, which is correctly called a “branch clamp”, is very popular, and is often used in distribution boards on floors to branch into apartments from the main line.

The insulation is removed from the ends of the wires for the length of the clamp, the wires are inserted between the plates with grooves in size, and are evenly clamped with four screws.

Outside, a dielectric casing is installed on the metal clamp, which protects the structure from short circuits against other conductive parts located nearby. The clamp size is selected by marking in accordance with the cross sections of the trunk and branch conductors.

If the cross-section of the connected wires is very large, then a method of connecting with copper-tinned lugs fastened with a bolt and nut is suitable.

Tips for a suitable section are crimped by press pliers or a hydraulic press at the ends of the wires, then tightly fixed to each other using a bolted connection.

The contact area is vast, such a connection is highly conductive and reliable. The finished connection can be further insulated. shrink tube or electrical tape.

See also at i.electricianexp.com

: