Categories: Electric installation work

Number of views: 110014

Comments on the article: 0

Wago terminals: types, characteristics, how to choose and how to use it correctly

Wago terminals: types, characteristics, how to choose and how to use correctly There are many ways to create contact between two or more conductors: terminals, lugs, sleeves, soldering, welding, twisting ... The German company Wago first introduced the design of spring-loaded terminal blocks in 1951 year, and now she is known as a manufacturer of popular connectors for wires. Small terminals for junction or junction boxes have been available since 1973. These terminals have their advantages, disadvantages and features, which we will consider in the article.

Prerequisites for spring terminals

Among popular connection methods can distinguish:

1. Twisting. Advantages: quickly completed, often without the aid of a tool and cost-free. Disadvantages: unreliable connection, weakens with time, contact disappears with oxidation, PUE is prohibited, cannot be used in fire hazardous rooms, aluminum and copper conductors cannot be twisted.

2. Bolted connection. More reliable than twisting, aluminum and copper can be connected through the washer. Disadvantages: weakens, weakens even faster when heated, it is not always convenient to work with bolts. Especially in the case of a short free section of wire, inconvenience during installation, for example, at a height, the connection turns out to be stern, it must be insulated.

3. Screw clamps (terminals). Everything is the same as the bolted connection, but also, if you pull the bolt, such a healed easily crack. Do not use a wire with a multi-wire core, without a ferrule. When tightened, they are flattened, wires can be damaged or contact may weaken over time. The advantage is that the terminal block in a plastic case can not be insulated if used in a dry environment.

4. The use of sleeves. Advantages: reliability, permitted in regulatory documents for use in electrical installations, the ability to protect conductors from quartz-grease lubrication from oxides. Disadvantages: crimping pliers are needed, it is not convenient and possible to crimp everywhere.

5. Soldering. Reliably, but cannot be used at high currents. When a large current flows, the junction can heat up and the solder melt (unlikely, but possible). Better to use paired with a sleeve. Disadvantages: you need a soldering iron, electricity to it.

6. Welding. The most reliable way to connect, you get an almost solid wire. It is twisted and welded. There is one drawback: a welding machine and power to it. However, it can be portable and run on battery power.

The options considered have their advantages and disadvantages, not all of them are allowed for use on an ongoing basis and are safe. For installation, you need to use convenient and reliable means. Unfortunately, reliable options from the above are not always possible to put into practice on a real object in a junction box or, for example, when connecting a chandelier.

VAGO terminal blocks have the following advantages:

-

no additional fixtures are needed for installation;

-

dissimilar wires (aluminum and copper) can be connected;

-

it is possible to connect conductors of different sections within the same terminal strip;

-

some models can be dismantled and reused;

-

Some models come with grease on the spring and busbar, which prevents oxides. This is especially true when working with aluminum conductors;

-

take up small places in the junction box;

-

insulated housing.

Review of popular WAGO models

Due to the ease of use, this method of connection has gained popularity, it is very convenient to use it for temporary connection to electricity, for example, at a construction site, the lever clamps will become indispensable. Generally, spring terminal blocks from the manufacturer VAGO can be divided into disposable and reusable (with lever clamp). The main series of cross sections which are connected by such terminals are 0.08-4 mm2, and the currents of such terminals are limited to 20-32A, depending on the model. Let's look at each of the species in particular.

Wago PUSH WIRE Flat Spring

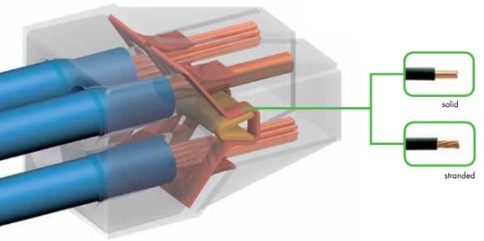

The terminal blocks of the 773 series are considered obsolete since they were among the first to appear on the market. Ideal for connecting aluminum and copper wires with a monolithic core, or with a multi-wire core of a low class of flexibility. The soft core cannot be inserted into the spring, although this can be done if it is tightly twisted and tinned with solder, then its end will become rigid.

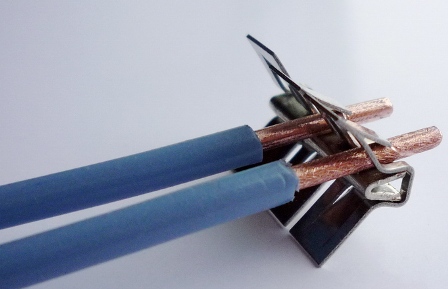

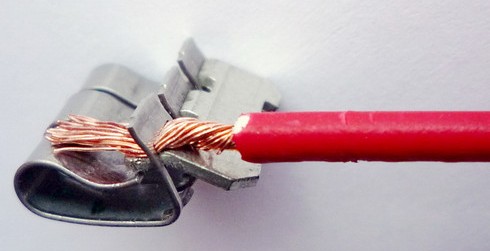

If you look at the spring from the side, it has a wedge-shaped contour. This design makes it easy to insert a wire. It is difficult to remove the wire from the terminal without damaging the spring or core, so they can be considered disposable.

In the photo you see two lived clamped in such a terminal. They lie on a C-shaped conductive core. The end of the wire should be flat, this will improve contact, facilitate the introduction of the conductor into the spring. It is better to remove the insulation with a special tool - a stripper.

Novice electricians neglect this and simply plan out the coating with a knife. So you can damage the conductor, make an incision, on which it can break off during operation. In flexible cables, part of thin wire veins can be planed in this way, thereby reducing the conductor cross section and worsening the future connection.

The 773 series is divided into 2 families:

1. Wago 773-30x. With an opaque body, quartz-vaseline lubricant inside the terminal, it removes oxidation from aluminum and prevents their appearance. The grease in the photo is visible. In this case, highly oxidized conductors must first be stripped.

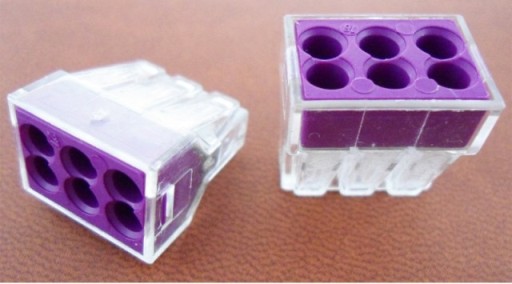

2. 773-32x series with transparent case. In general, similar connectors, but they are not greased.

The advantage is the ability to control the process of introducing the conductor, to evaluate the quality of its fastening.

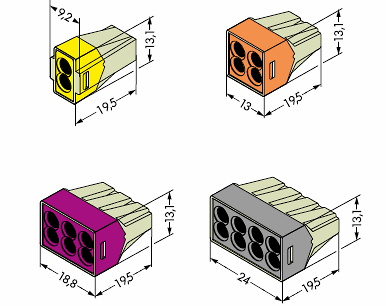

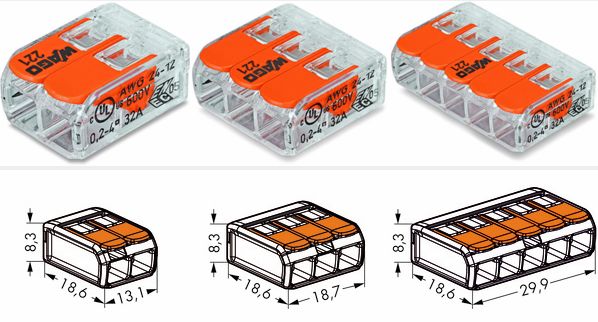

I already mentioned that VAGOs are quite compact, their length is 19.5 mm, the width of the model is 4 wires is 13 mm, and the height is 13.1, below are the drawings of four different versions of this series.

The terminals of this series pass current up to 20-24 A, operating voltage 380-600V, discharge voltage - 4 kV, withstand operating temperatures up to 85 degrees.

Such characteristics are enough for installing home electrical wiring, lighting, sockets. They perfectly fit the free space during the installation of the chandelier and in the junction box with a tight wiring. To connect powerful electrical appliances (5 kW and above), you need to use other connection methods.

It would be rash if the electrician could not check the voltage on the cables with this connection method, a window for the probe is provided for this. It comes in about 6 mm.

To connect the cable, you need to remove the insulation by 10-12 mm, and then insert it into the terminal block hole. After which you cannot pull it back without undue effort.

Reusable lever VAGO, Cage Clamp system

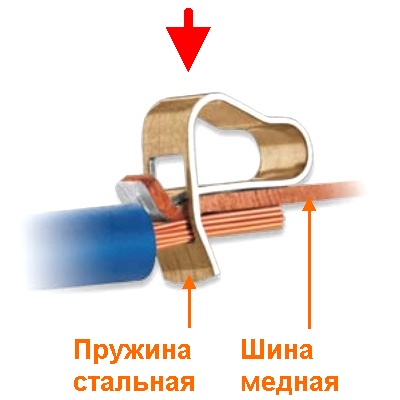

To solve the problem of connecting stranded wires and to realize the possibility of reusable use, WAGO revised the design of the clamp, and, changing the shape of the spring, achieved the task. Such a system is called Cage Clamp. Its spring resembles a carbine.

If you press the clamp on it, it moves and the window into which the cable is inserted expands. Thus, it became possible to remove the cable from the terminal or insert into it flexible wire (multi-wire core). The red arrow in the figure indicates the direction in which to press on the spring.

The most common terminal blocks with such a spring at the time of writing are WAGO 222 series.

The wire stripped from insulation by 8-10 millimeters is inserted into the WAGO 222 until it stops.

At the same time, the lever is raised, the spring is compressed, and the window is opened. After that, lower the lever and the connection is ready - the wire will be clamped securely. Wherein use of tips or tinning of stranded wires is optional.

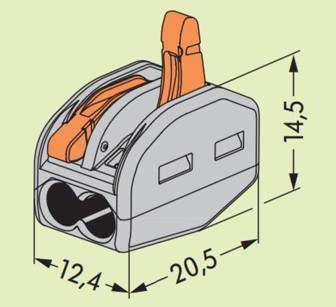

It is possible to connect the same core cross-section range in them: 0.08-4 mm2, the maximum allowable current is 32A. Overall dimensions and drawing are presented in the figure below.

They also have a measuring window where you can insert the probe of a multimeter or a bipolar voltage indicator.

In the photo you see the option of connecting the chandelier with such a terminal strip, everything is quite compact, and when dismantling it, you do not have to unwind the insulation or bite off the cable. This eliminates the need to change the wires in the lamp, in case of unsuccessful dismantling or, even worse, to grind the ceiling to connect the lamp in place.

WAGO 221 - even more compact, have the same lever mechanism, but are made in a transparent case.

Below you see their dimensions, drawings and appearance.

224 Series Terminal Blocks used to connect lighting devices, but no one forbids you to use other WAGO models for these purposes. They differ in the butt joint, which in some cases is convenient, and there is no need to bend the core.

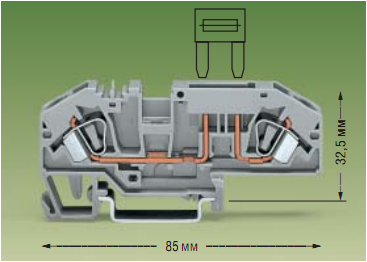

WAGO on a din rail

The manufacturer has a separate set of terminal blocks for DIN rail mounting. There are many varieties of them, the figure below shows an example with a fuse. An LED indicator or disconnector can be installed. It is convenient to use for the installation of complex circuits in switchboards.

Design features

On the Internet, experts are discussing whether it is safe to use the connectors of this brand, or is it just a marketing ploy and PR? The main reason for these conversations is that the contact area in such terminal blocks is relatively small. Clamping a round conductor to a flat busbar and spring gives a point contact, while classic screw clamps have a round shape, like sleeves and terminal blocks.

On the other hand, for a flexible conductor with a multi-wire core, this design will provide a reliable connection with a good contact spot, even if the wires take the form of a window, the spring contact will fix them reliably, which cannot be achieved in classical screw clamps.

The video shows a comparison of the heating of different compounds. Draw your own conclusions. My opinion is that these terminals are perfect for household power supply, they have passed international certifications, withstand rated parameters, PUE are allowed, an insulated case will save meters of electrical tape in the distribution boxes and speed up the installation process.

Such characteristics do not allow exceeding the permissible current, not only the contact will be heated, but also the cable with subsequent damage to the insulation and short circuits.

Do not use aluminum cables in 222, 221 and similar clamps without quartz-vaseline paste. They will oxidize over time, contact will deteriorate, and will begin to warm up. This will deteriorate even more due to deformation of the metal parts of the clamp, as a result of which carbonization or fire may occur.

Conclusion: The VAGO terminals must be used for their intended purpose and only where the current never exceeds the rated 32A. A tight long twist provides greater contact, and to make it more reliable you can zagilizovat, even better to weld it.

See also on our website:How to distinguish a good Wago terminal block from a fake

See also at i.electricianexp.com

: