Categories: Featured Articles » Sharing experience

Number of views: 36483

Comments on the article: 0

How to make an electromagnet at home

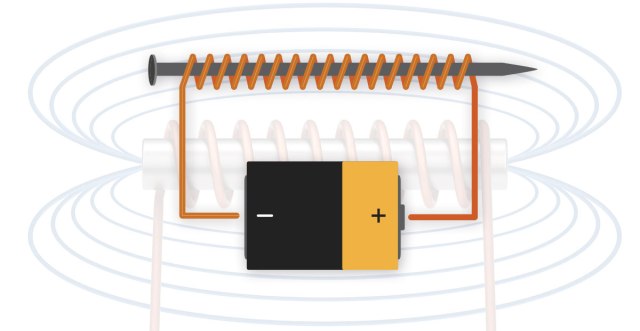

Electromagnet – an artificial magnet in which a magnetic field arises and is concentrated in the ferromagnetic core as a result of the passage of an electric current through the winding surrounding it, i.e. when passing current through the coil, the core placed inside it acquires the properties of a natural magnet.

The scope of electromagnets is very extensive. They are used in electrical machines and devices, in automation devices, in medicine, in various kinds of scientific research. Most often, electromagnets and solenoids are used to move some kind of mechanisms, and in factories for lifting loads.

So, for example, the lifting electromagnet is a very convenient, productive and economical mechanism: maintenance personnel are not required to secure and release the transported cargo. It is enough to put an electromagnet on the transported load and turn on the electric current in the coil of the electromagnet and the load will be attracted to the electromagnet, and to free it from the load, you just need to turn off the current.

The design of the electromagnet is easy to repeat and in essence is nothing but the core and the coil of the conductor. In this article we will answer the question of how to make an electromagnet with your own hands?

How does an electromagnet (theory)

If an electric current flows through the conductor, a magnetic field is generated around this conductor. Since current can only flow when the circuit is closed, the conductor should be a closed loop, such as a circle, which is the simplest closed loop.

Previously, a conductor rolled up in a circle was often used to observe the action of current on a magnetic needle located in its center. In this case, the arrow is at an equal distance from all parts of the conductor, making it easier to observe the effect of current on the magnet.

In order to enhance the effect of an electric current on a magnet, it is first possible to increase the current. However, if you go around the conductor through which some current flows twice around the circuit it covers, then the effect of the current on the magnet will double.

Thus, this action can be increased many times by rounding the conductor an appropriate number of times around a given circuit. The resulting conductive body, consisting of individual turns, the number of which can be arbitrary, is called a coil.

Recall the course of school physics, namely, that when an electric current flows through a conductor magnetic field occurs. If the conductor is rolled into a coil, the lines of magnetic induction of all the turns will be formed, and the resulting magnetic field will be stronger than for a single conductor.

The magnetic field generated by an electric current, in principle, has no significant differences compared to a magnetic field, if we return to electromagnets, then the formula for its traction force looks like this:

F = 40550 ∙ B2∙ S,

where F is the traction force, kg (force is also measured in Newtons, 1 kg = 9.81 N, or 1 N = 0.102 kg); B - induction, T; S is the cross-sectional area of the electromagnet, m2.

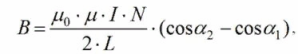

That is, the traction force of an electromagnet depends on magnetic induction, consider its formula:

Here U0 is the magnetic constant (12.5 * 107 Gn / m), U is the magnetic permeability of the medium, N / L is the number of turns per unit length of the solenoid, I is the current strength.

It follows that the force with which the magnet attracts something depends on the current strength, the number of turns and the magnetic permeability of the medium. If there is no core in the coil, the medium is air.

Below is a table of relative magnetic permeabilities for different media. We see that in air it is 1, while in other materials it is tens or even hundreds of times more.

In electrical engineering, a special metal is used for cores, it is often called electrical or transformer steel. In the third row of the table you see "Iron with Silicon" in which the relative magnetic permeability is 7 * 103 or 7000 GN / m.

This is the average value for transformer steel. It differs from the usual just the same silicon content. In practice, its relative magnetic permeability depends on the applied field, but we will not go into details. What gives the core in the coil? The core of electrical steel will enhance the magnetic field of the coil about 7000-7500 times!

All you need to remember to start with is that it depends on the core material inside the coil magnetic induction, and the force with which the electromagnet will pull depends on it.

Practice

One of the most popular experiments that are carried out to demonstrate the occurrence of a magnetic field around a conductor is the experience with metal chips. The conductor is covered with a sheet of paper and magnetic chips are poured onto it, then an electric current is passed through the conductor, and the chip changes its position somehow on the sheet. This is almost an electromagnet.

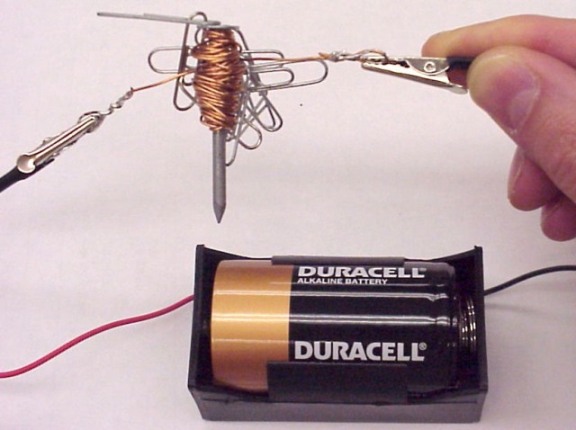

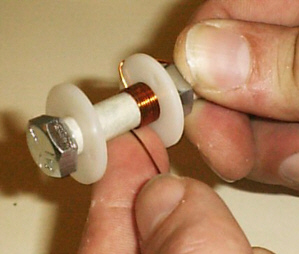

But for an electromagnet, simply attracting metal chips is not enough. Therefore, it is necessary to strengthen it, based on the foregoing - you need to make a coil wound on a metal core. The simplest example would be an insulated copper wire wound around a nail or bolt.

Such an electromagnet is able to attract different pins, scrapie and the like.

As a wire, you can use either any wire in PVC or other insulation, or a copper wire in varnish insulation such as PEL or PEV, which are used for the windings of transformers, speakers, motors, etc. You can find it either new in coils, or rewind from the same transformers.

10 Nuances of manufacturing electromagnets in simple words:

1. The insulation along the entire length of the conductor must be uniform and intact so that there are no inter-turn faults.

2. The winding should go in one direction as on a spool of thread, that is, you cannot bend the wire 180 degrees and go in the opposite direction. This is due to the fact that the resulting magnetic field will be equal to the algebraic sum of the fields of each coil, if you do not go into details, then the coils wound in the opposite direction will generate an electromagnetic field of opposite sign, as a result of the field will be subtracted and as a result the force of the electromagnet will be less and if there will be the same number of turns in one and the other direction, the magnet will not attract anything at all, since the fields suppress each other.

3. The strength of the electromagnet will also depend on the current strength, and it depends on the voltage applied to the coil and its resistance. The resistance of the coil depends on the length of the wire (the longer it is, the greater it is) and its cross-sectional area (the larger the cross section, the less resistance) an approximate calculation can be carried out according to the formula - R = p * L / S

4. If the current is too high, the coil will burn.

5. With direct current - the current will be greater than with alternating current due to the influence of reactance inductance.

6. When working on alternating current - the electromagnet will buzz and rattle, its field will constantly change direction, and its traction force will be less (twice) than when working on constant. At the same time, the core for alternating current coils is made of sheet metal, gathering together, while the plates are isolated from each other by varnish or a thin layer of scale (oxide), the so-called blends - to reduce losses and Foucault currents.

7. With the same traction force, an alternating current electric magnet will weigh twice as much, and the dimensions will increase accordingly.

8. But it is worth considering that AC electromagnets are faster than DC magnets.

9. Cores of DC electromagnets

10. Both types of electromagnets can work both on direct and alternating current, the only question is what kind of power it will possess, what losses and heating will occur.

3 ideas for an electromagnet from available tools in practice

As already mentioned, the easiest way to make an electromagnet is to use a metal rod and a copper wire by picking up one and the other for the required power. The supply voltage of this device is selected empirically based on the current strength and heating of the structure. For convenience, you can use a plastic spool of thread or the like, and choose a core — a bolt or a nail — under its inner hole.

The second option is to use an almost ready-made electromagnet. Think of electromagnetic switching devices - relays, magnetic starters and contactors. For use on direct current and a voltage of 12V, it is convenient to use a coil from automotive relays. All you need to do is remove the case, break the movable contacts and connect the power.

For work from 220 or 380 volts it is convenient to use coils magnetic starters and contactorsThey are wound on a mandrel and can be easily removed. Select the core based on the cross-sectional area of the hole in the coil.

So you can turn on the magnet from the outlet, and it is convenient to adjust its strength if you use a rheostat or limit the current using powerful resistance, for example, nichrome spiral.

See also at i.electricianexp.com

: