Categories: Featured Articles » Novice electricians

Number of views: 206,509

Comments on the article: 6

Electric heating elements, heating elements, types, designs, connection and testing

Electric heating elements are used in household and industrial equipment. The use of various heaters is known to all. These are electric stoves, ovens and ovens, electric coffee makers, electric kettles and heating appliances of various designs.

Electric water heaters, commonly referred to as boilers, also contain heating elements. The basis of many heating elements is a wire with high electrical resistance. And most often this wire is made of nichrome.

Open nichrome spiral

The oldest heating element is perhaps the usual nichrome spiral. Once upon a time, home-made electric stoves, water boilers and goat heaters were in use. Having at hand a nichrome wire that could “get hold of” in production, making a spiral of the required power did not present any problems.

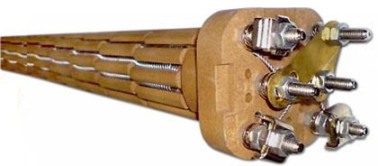

The end of the wire of the desired length is inserted into the cut of the winch, the wire itself is passed between two wooden blocks. The vice must be clamped so that the entire structure is held as shown in the figure. The clamping force must be such that the wire passes through the bars with some effort. If the clamping force is large, then the wire will simply break.

Figure 1. Nichrome spiral winding

By rotating the collar, the wire is pulled through the wooden bars, and carefully, turn to turn, is laid on a metal rod. In the arsenal of electricians there was a whole set of wrenches of various diameters from 1.5 to 10 mm, which made it possible to wind spirals for all occasions.

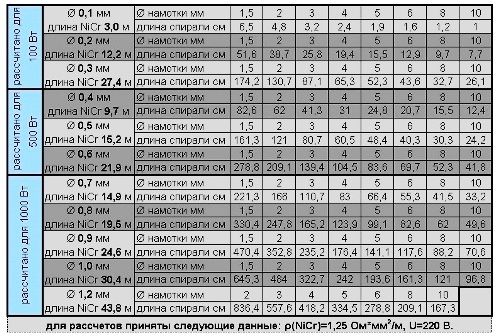

It was known what diameter the wire is and what length is required for winding the spiral of the required power. These magic numbers can still be found on the Internet. Figure 2 shows a table that shows data on spirals of various capacities at a supply voltage of 220V.

Figure 2. Calculation of the electric spiral of the heating element (click on the picture to enlarge)

Everything is simple and clear here. Having set the required power and the diameter of the nichrome wire at hand, it remains only to cut a piece of the desired length and wind it onto a mandrel of the corresponding diameter. At the same time, the table shows the length of the resulting spiral. And what if there is a wire with a diameter not specified in the table? In this case, the spiral will just have to be calculated.

How to calculate a nichrome spiral

If necessary, calculate the spiral is quite simple. As an example, the calculation of a spiral made of nichrome wire with a diameter of 0.45 mm (there is no such diameter in the table) with a power of 600 W for a voltage of 220V. All calculations are performed according to Ohm's law.

About how to convert amperes to watts and, conversely, watts to amperes:

How many amperes are in amperes, how to convert amperes into watts and kilowatts

First, you should calculate the current consumed by the spiral.

I = P / U = 600/220 = 2.72 A

To do this, it is enough to divide the set power by voltage and get the amount of current passing through the spiral. Power in watts, voltage in volts, result in amperes. All according to the SI system.

Using the current known now, calculating the required resistance of the spiral is quite simple: R = U / I = 220 / 2.72 = 81 Ohms

The formula for calculating the resistance of a conductor is R = ρ * L / S,

where ρ is the specific resistance of the conductor (for nichrome 1.0 ÷ 1.2 Ohm • mm2 / m), L is the length of the conductor in meters, S is the cross section of the conductor in square millimeters. For a conductor with a diameter of 0.45 mm, the cross section is 0.159 mm2.

Hence L = S * R / ρ = 0.159 * 81 / 1.1 = 1170 mm, or 11.7 m.

In general, the calculation is not so complicated.Indeed, the manufacture of a spiral is not so difficult, which, undoubtedly, is the advantage of ordinary nichrome spirals. But this advantage is blocked by many shortcomings inherent in open spirals.

First of all, this is a rather high heating temperature - 700 ... 800˚C. The heated spiral has a faint red glow, accidentally touching it can cause a burn. In addition, electric shock is possible. A red-hot spiral burns out the oxygen of the air, attracts dust particles to itself, which, when burned, give a very unpleasant aroma.

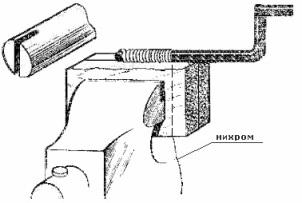

But the main drawback of open spirals should be considered their high fire hazard. Therefore, the fire department simply prohibits the use of heaters with an open spiral. Such heaters, first of all, include the so-called "goat", the design of which is shown in Figure 3.

Figure 3. Homemade goat heater

This is how the wild “goat” turned out: it was deliberately made carelessly, simply, even very badly. A fire with such a heater will not have to wait long. A more advanced design of such a heater is shown in Figure 4.

Figure 4. "Goat" home

It is easy to see that the spiral is closed by a metal casing, it is this that prevents touching heated parts of live parts. The fire hazard of such a device is much less than that shown in the previous figure.

See this topic:Why are the "goat" and a homemade boiler dangerous?

Once upon a time in the USSR, heaters-reflectors were produced. In the center of the nickel-plated reflector there was a ceramic cartridge, into which, like a bulb with an E27 cap, a 500W heater was screwed in. The fire hazard of such a reflector is also very high. Well, I somehow did not think in those days what the use of such heaters could lead to.

Figure 5. Reflex heater

It is quite obvious that various heaters with an open spiral can, contrary to the requirements of the fire inspection, be used only under vigilant supervision: if you leave the room - turn off the heater! Better yet, just stop using this type of heater.

Closed spiral heating elements

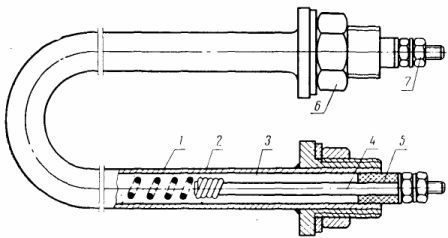

To get rid of an open spiral, Tubular Electric Heaters - TENs were invented. The design of the heater is shown in Figure 6.

Figure 6. The design of the heater

The nichrome spiral 1 is hidden inside a thin-walled metal tube 2. The spiral is isolated from the tube by filler 3 with high thermal conductivity and high electrical resistance. Periclase (a crystalline mixture of magnesium oxide MgO, sometimes with impurities of other oxides) is most often used as a filler.

After filling with an insulating composition, the tube is pressed, and under high pressure the periclase turns into a monolith. After such an operation, the spiral is rigidly fixed, therefore, electrical contact with the body - tube is completely excluded. The design is so strong that any heater can be bent if the design of the heater requires it. Some heating elements have a very bizarre shape.

The spiral is connected to the metal leads 4, which exit through the insulators 5. The lead wires are connected to the threaded ends of the leads 4 with nuts and washers 7. The heating elements are fastened in the device case with nuts and washers 6, which ensure, if necessary, the tightness of the connection.

Under observance of operating conditions, such a design is quite reliable and durable. This is precisely what led to the very widespread use of heating elements in devices for various purposes and designs.

According to the operating conditions, the heating elements are divided into two large groups: air and water. But that's just that name. In fact, air heating elements are designed to work in various gas environments.Even ordinary atmospheric air is a mixture of several gases: oxygen, nitrogen, carbon dioxide, there are even impurities of argon, neon, krypton, etc.

The air environment is very diverse. It can be calm atmospheric air or a stream of air moving at a speed of several meters per second, as in fan heaters or heat guns.

The heating of the heater shell can reach 450 ˚C and even more. Therefore, for the manufacture of the outer tubular shell, various materials are used. It can be ordinary carbon steel, stainless steel or heat-resistant, heat-resistant steel. It all depends on the environment.

To improve heat transfer, some heating elements are equipped with ribs on the tubes in the form of a wound metal tape. Such heaters are called finned. The use of such elements is most appropriate in a moving air environment, for example, in fan heaters and heat guns.

Water heating elements are also not necessarily used in water; this is the general name for various liquid media. It can be oil, fuel oil and even various aggressive liquids. Liquid TENY used in electric boilers, distillers, electric desalination plants and just titans for boiling drinking water.

The thermal conductivity and heat capacity of water is much higher than that of air and other gaseous media, which provides, in comparison with the air, a better, faster heat removal from the heater. Therefore, with the same electrical power, the water heater has smaller geometric dimensions.

Here we can give a simple example: when boiling water in an ordinary electric kettle, the heater can be red-hot, and then burn to holes. The same picture can be observed with ordinary boilers, designed to boil water in a glass or in a bucket.

The given example clearly demonstrates that water heating elements should never be used for work in the air. You can use air heating elements to heat the water, but you just have to wait a long time until the water boils.

Not to the advantage of water heating elements will be a layer of scale formed during operation. Scale, as a rule, has a porous structure, and its thermal conductivity is small. Therefore, the heat generated by the spiral goes into the liquid poorly, but the spiral inside the heater warms up to a very high temperature, which will sooner or later lead to its burnout.

To prevent this from happening, it is advisable to periodically clean the heating elements using various chemicals. For example, in a television advertisement, Calgon is recommended for protecting washing machine heaters. Although about this tool, there are many different opinions.

How to get rid of scale

In addition to chemicals for protection against scale, various devices are used. First of all, these are magnetic water converters. In a powerful magnetic field, crystals of "hard" salts change their structure, turn into flakes, become smaller. Scale is less active from such flakes; most of the flakes are simply washed away by a stream of water. This ensures the protection of heaters and pipelines from scale. Magnetic filter converters are produced by many foreign companies, such companies exist in Russia. Such filters are available both mortise and overhead type.

Electronic water softeners

Recently, electronic water softeners are becoming increasingly popular. Outwardly, everything looks very simple. A small box is installed on the pipe, from which the antenna wires come out. Wires are wound around the pipe, and you don’t even need to peel off the paint. The device can be installed in any accessible place, as shown in Figure 7.

Figure 7. Electronic water softener

The only thing you need to connect the device is a 220V socket.The device is designed for long-term switching on, it does not need to be turned off periodically, since switching off will cause the water to become hard again, scale will form again.

The principle of operation of the device is reduced to the emission of vibrations in the range of ultrasonic frequencies, which can reach up to 50KHz. The oscillation frequency is controlled using the control panel of the device. Radiation is produced in batches several times per second, which is achieved using the built-in microcontroller. The power of fluctuations is small, therefore, such devices do not pose any threat to human health.

The expediency of installing such devices is easy to determine. It all comes down to determining how hard the water flows from the water pipe. Here you don’t even need any “abstruse” appliances: if your skin becomes dry after washing, white stains appear on the tile from water splashes, scale appears in the kettle, the washing machine erases more slowly than at the beginning of operation - hard water definitely flows from the tap. All this can lead to failure of the heating elements, and therefore the kettles or washing machines themselves.

Hard water does not dissolve various detergents - from ordinary soaps to superfashionable laundry detergents. As a result, you have to put more powders, but this helps a little, since the crystals of hardness salts are retained in the tissues, the washing quality leaves much to be desired. All of the listed signs of water hardness eloquently indicate that it is necessary to install water softeners.

Connection and verification of heating elements

When connecting the heater, a wire of a suitable cross-section must be used. It all depends on the current flowing through the heater. Most often, two parameters are known. This is the power of the heater itself and the supply voltage. In order to determine the current, it is enough to divide the power by the supply voltage.

A simple example. Let there be a heating element with a power of 1 kW (1000 W) for a supply voltage of 220V. For such a heater, it turns out that the current is

I = P / U = 1000/220 = 4.545A.

According to the tables placed in the PUE, such a current can provide a wire with a cross section of 0.5 mm2 (11A), but in order to ensure mechanical strength it is better to use a wire with a cross section of at least 2.5 mm2. Just such a wire is most often supplied with electricity to outlets.

But before making the connection, you should make sure that even the new, just purchased TEN is in good condition. First of all, it is necessary to measure its resistance and check the integrity of the insulation. The resistance of the heating element is quite simple to calculate. To do this, it is necessary to square the supply voltage, and divide by power. For example, for a 1000W heater, this calculation looks like this:

220 * 220/1000 = 48.4ohm.

Such a resistance should be shown by a multimeter when connecting it to the terminals of the heater. If the spiral is broken, then, naturally, the multimeter will show a break. If we take a heating element of a different power, then the resistance, of course, will be different.

To check the integrity of the insulation, measure the resistance between any of the terminals and the metal housing of the heater. The resistance of the filler-insulator is such that at any measurement limit the multimeter should show a break. If it turns out that the resistance is zero, then the spiral has contact with the metal housing of the heater. This can happen even with a new one, just bought by a heating element.

Generally used to test insulation special megaohmmeter device, but not always and not all have it at hand. So a normal multimeter test is also quite suitable. At least such a check must be done.

As already mentioned, the heating elements can be bent even after filling with an insulator. There are various types of heaters: in the form of a straight tube, U-shaped, rolled into a ring, snake or spiral.It all depends on the device of the heating device in which the heater is supposed to be installed. For example, in a flowing water heater of a washing machine, TENs are twisted into a spiral.

Some TENY have elements of protection. The simplest protection is a thermal fuse. Well, if it burned down, then you have to change the whole heater, but it won’t reach the fire. There is a more complex protection system that allows the use of a heater after its operation.

One of such protections is a protection based on a bimetallic plate: heat from an overheated heating element bends the bimetallic plate, which opens the contact and de-energizes the heating element. After the temperature drops to an acceptable value, the bimetallic plate extends, the contact closes and the heater is ready for operation again.

TENY with a temperature regulator

In the absence of hot water, you have to use boilers. The design of the boilers is quite simple. This is a metal container hidden in a "fur coat" from a heat insulator, on top of which is a decorative metal case. A thermometer is embedded in the case, showing the temperature of the water. The design of the boiler is shown in Figure 8.

Figure 8. Storage boiler

Some boilers contain a magnesium anode. Its purpose is protection against corrosion of the heater and the internal tank of the boiler. The magnesium anode is a consumable; it has to be periodically changed during boiler maintenance. But in some boilers, apparently of a cheap price category, such protection is not provided.

As a heating element in boilers, a heater with a temperature regulator is used, the design of one of them is shown in Figure 9.

Figure 9. TEN with a temperature regulator

A microswitch is located in the plastic box, which is triggered by a liquid temperature sensor (a direct tube next to the heater). The shape of the heater itself can be the most diverse, the figure shows the simplest. It all depends on the power and design of the boiler. The degree of heating is controlled by the position of the mechanical contact controlled by a white round handle located at the bottom of the box. There are also terminals for supplying electric current. The heater is fastened with thread.

Wet and Dry Heaters

Such a heater is in direct contact with water, so this heater is called "wet." The service life of a “wet” heating element is within 2 ... 5 years, after which it has to be changed. In general, the service life is short.

To increase the service life of the heating element and the entire boiler as a whole, the French company Atlantic in the 90s of the last century developed the design of a “dry” heating element. To put it simply, the heater was hidden in a metal protective flask that excluded direct contact with water: the heating element is heated inside the flask, which transfers heat to the water.

Naturally, the temperature of the flask is much lower than the heating element itself; therefore, the formation of scale with the same water hardness is not so intense, more heat is transferred to the water. The service life of such heaters reaches 10 ... 15 years. This is true for good operating conditions, especially the stability of the supply voltage. But even in good conditions, “dry” heating elements also produce their own resources, and they have to be changed.

Here one more advantage of the “dry” heating element technology is revealed: when replacing the heater, there is no need to drain the water from the boiler, for which it should be disconnected from the pipeline. Simply turn out the heater and replace it with a new one.

Atlantic, of course, patented its invention, after which it began to sell the license to other companies. At present, other companies, for example, Electrolux and Gorenje, also produce boilers with a “dry” heating element. The design of the boiler with a “dry” heating element is shown in Figure 10.

Figure 10. Boiler with a “dry” heater

By the way, the figure shows a boiler with a ceramic steatite heater. The device of such a heater is shown in Figure 11.

Figure 11. Ceramic Heater

On the ceramic base is fixed a conventional open spiral of high resistance wire. The heating temperature of the spiral reaches 800 degrees and is transferred to the environment (air under a protective shell) by convection and heat radiation. Naturally, such a heater as applied to boilers can only work in a protective shell, in air, direct contact with water is simply excluded.

The spiral can be wound in several sections, as evidenced by the presence of several terminals for connection. This allows you to change the power of the heater. The maximum specific power of such heaters does not exceed 9W / cm2.

The condition for the normal operation of such a heater is the absence of mechanical loads, bends and vibrations. The surface should not be contaminated by rust or oil stains. And, of course, the more stable the supply voltage, without surges and surges, the more durable the heater.

But electrical technology does not stand still. Technologies are developing, improving, therefore, in addition to heating elements, a wide variety of heating elements have been developed and are being successfully applied. These are ceramic heating elements, carbon heating elements, infrared heating elements, but this will be the topic for another article.

Continuation of the article:Modern heating elements

See also at i.electricianexp.com

: