Categories: Electric installation work

Number of views: 16476

Comments on the article: 0

What are the nozzles for the grinder and rotary hammer for electrical work

No electrical work in the building is complete without wall chipping. To lay hidden wiring, a wall (groove) is first made in the wall, then cables are laid into it, after which the wall with the wiring is sealed with a solution.

Traditionally, in the process of gating, a special power tool called shtroborezom (furrowed), then use a hammer drill with a special nozzle in the form of a scapula to completely clear the furrow.

Finally, the wiring is laid in the gate. In general, channels in concrete or brick walls are made not only for wiring and other cables, but also for water and sewer pipes, ventilation ducts and all that sort of thing.

In addition to wall chipping, electrical work includes: drilling holes for sockets, for soldering boxes, drilling holes for plastic mounting dowels, etc. At each stage of electrical work, a special tool is needed, and more importantly, special nozzles. Just about nozzles (to grinders and perforators) will be discussed in this article.

In fairness, we note that a correctly selected working tool is already half of the solved problem. And since a good, high-quality tool is not cheap, you can always rent it or buy it for repair, and then sell it, because ordering electrical work is usually more expensive than doing it yourself. Therefore, many act so that they do the installation themselves.

A powerful punch is suitable for drilling holes, in addition, with its help you can actually make a small furrow. But for strobing in large volumes it is better to use a stroborez or at least a grinder with a disk for concrete, equipped with a special modified nozzle. For rosettes, crowns will be required, but first things first.

Stroborez

A standard chamfer cutter simultaneously cuts two discs on concrete, so the power of the chamfer is, in principle, higher than that of a grinder. It remains for the worker to set the distance between the cutting discs, adjust the depth of the furrow, and simply make a stroba.

The shtroborez is equipped with a protective cover and a clamping platform, so it is quite simple to work with it, in addition, most shtroborez models support the connection of the vacuum cleaner hose to a special nozzle so that the concrete dust can be removed instead of spreading it everywhere, and the most dangerous thing is to inhale. The best models of chippers have protection against overheating of the disk and blocking from accidental switching on. After cutting the furrows, a puncher with a spatula will turn on.

Grinder nozzle

And if there is no shtroboreza? Then the Bulgarian will come to the rescue. But in order to perform a gating with a grinder, it is necessary, firstly, a concrete disk, and secondly, the tool must have a special protective cover so that flying pieces do not cause harm to the worker, or in case of a disk expansion - protect it from serious injuries.

This casing (home-made or ready) turns the grinder into a kind of single-disk shtorez, this is a modified protective casing. It has both a nozzle for connecting a vacuum cleaner and a clamping platform. Some models allow you to adjust the distance of the departure of the disk from the casing, so that you can adjust the depth of the sawed strobes.

To adjust the cutting depth, unscrew the bracket bolt, raise or lower the grinder body or casing, then tighten the bolt. So the disc will protrude to the desired depth.

Strobing grinder:

By the way, the smaller the depth of the furrow - the easier it will then be to work with a puncher.But the disk is still the same anyway - it will be necessary to cut two times on the same path with the exact distance between the cuts being observed, since the device of the grinder itself does not allow the installation of two disks at the same time even a couple of centimeters between them. The finished chipper, of course, from the point of view of convenience and practicality, is better for these works.

Hammer drill bits

To hollow the middle of the furrow, you need a hammer with a nozzle in the form of a scapula. The width of the blade is selected based on the width of the strobes. How many cables will be laid in the gate and what will be their cross section?

Based on this, and choose the size of the scapula. A flat shoulder blade and a peak are all that is needed to gouge a groove accurately. It is better, of course, to have a set of blades for a hammer drill of different widths and shapes. With the help of these blades, you can also hollow out niches for shields, they will also help in the manufacture of holes for socket boxes.

To drill holes for the sockets, for the punch you will need a nozzle - a crown. A crown for concrete, wood or brick - is selected based on the material of your walls. Using such a nozzle, you can make a landing hole for a socket (and for a plastic socket) in a matter of seconds.

The crown for concrete is, in principle, suitable for wood and brick, just install it on a hammer drill. When a circle is drilled with a crown in the wall, it will be possible to free the round hole from excess concrete (brick, wood) with a chisel and hammer, or with the help of a spatula.

To start plugging dowels and other cable fasteners, you must first make holes in the wall for them. This is again done with a hammer drill (especially when it comes to concrete) with a drill.

Having a set of drills for a particular type of wall material, with diameters from 6 to 14 mm, with some effort, you will cope with the task. It is best to buy augers without stinting, otherwise you will have to change them too often in the process of work.

In addition to the article

Homemade drill bits

It is known that when conducting electrical work, first preliminary preparation of walls, ceilings, floors for hidden wiring of all types (power, telephone, antenna) of junction boxes and sockets is required. Here carbide drills of various lengths (up to 800 mm and above) and nozzles for them are needed.

A few years ago, to carry out electrical work on construction sites, I inexpensively purchased a Bosch rotary hammer without a set of interchangeable tools. When he tried to buy the right tool, it turned out that its total cost is more than the cost of a purchased hammer drill.

And then I decided to try to make on my own the most necessary tool, without which it is impossible to do when performing electrical work. And then, it’s always nice to try to do something useful with your own hands.

I had to drill walls about 1 m thick to supply new wiring in old houses. But drills of this length and with the “SDS plus” shank were then incredibly expensive (and even now there are many).

Therefore, I used steel rods as such drills (a better calibrated "self-propelled") with brazed carbide inserts of the VK8T type (or similar) and then specially sharpened on a diamond wheel. The diameters of these rods are 6, 8, 9.10 mm and lengths from 200 to 1000 mm, respectively. The longer the length, the larger the diameter of the drill.

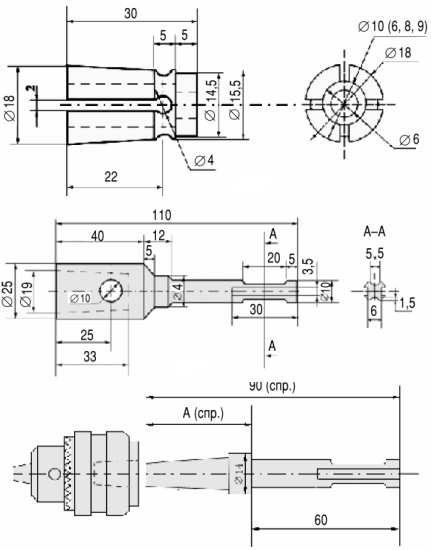

For their fastening into the perforator cartridge, I made an adapter - a cantilever holder and a set of collets of the same diameter as the drill, i.e. 6, 8, 9, 10 mm. The adapter and collets are made of X12 steel and then subjected to heat treatment to give them the necessary hardness (42–46 units).

The tool holder shank is adapted for SDS Plus standard perforator cartridges, which transfers the rotational impact movement to the interchangeable tool.To expand the capabilities of the acquired punch (and it has two operating modes: rotary and impact-rotary) I made an adapter for a 3-jaw chuck with a key.

Since this cartridge was available with a seat for a Morse cone, the adapter also has a Morse cone on one side and a “SDS plus” shank on the other. Thus, it became possible to use a hammer drill as a regular but powerful drill and clamp ordinary drills with a diameter of 1–9 mm and other nozzles with cylindrical shanks up to 9 mm inclusive into a manufactured adapter with a chuck. The material is the same, X12 steel, which then underwent heat treatment.

As practice has shown, these homemade devices have been very successful, durable and inexpensive to manufacture. And their price, taking into account all the manufacturing costs, turned out to be several times lower than the existing prices for branded similar nozzles.

The figure above shows the sketches of the collet, holder and cartridge holder. The dimensions of the shanks of the holder and the drill chuck are the same, therefore, the dimensions of the shank are not indicated in the figure. Dimensions A (reference) and 90 (reference) in the third figure are for reference and depend on the particular cartridge.

The first figure shows a collet with an inner diameter of 10 mm. Three other collets have diameters of 6, 8, 9 mm with the same dimensions. With high-quality manufacturing and heat treatment, these nozzles are very durable, practical and fully cover the costs of their manufacture. In the future, special nozzles and adapters for the “Dauer ERP1000” brand puncher were made, which manufacturers do not produce at all.

See also at i.electricianexp.com

: