Categories: Featured Articles » Novice electricians

Number of views: 85975

Comments on the article: 5

How to do splicing and branching wires using twisting

When repairing electrical wiring or home electrical appliances, quite often the question arises of splicing electrical wires or creating a branch of the electrical network. The main task in this case is to ensure high-quality electrical contact at the junction of the wires and its reliable insulation.

When repairing electrical wiring or home electrical appliances, quite often the question arises of splicing electrical wires or creating a branch of the electrical network. The main task in this case is to ensure high-quality electrical contact at the junction of the wires and its reliable insulation.

Splicing wires ctwist

When preparing the wires for splicing (branching), it is necessary to free a section of the wire from insulation. When using special tools to remove insulation, this operation takes a minimum of time and does not require skills from the master.

But, as a rule, only a sharp knife is listed in home tools and then you need to keep in mind some simple tricks:

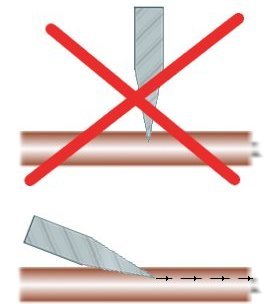

- it is impossible to incise the insulation by holding the blade of the mounting knife perpendicular to the wire. The sharp edge of the blade will leave a microscopic circular notch on the center conductor and the wire will break at this point. Even if this does not happen when cutting the wire, it will certainly happen during its further operation;

- when cutting insulation, the knife should slide at an acute angle to the conductor (as with pencil sharpening) and carefully remove the chips behind the chips;

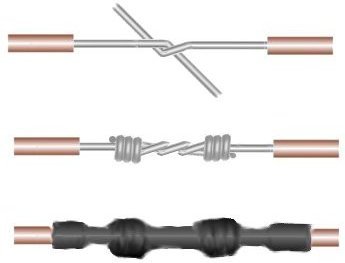

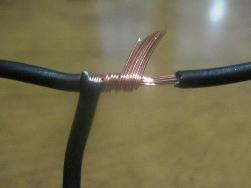

- the stripped ends of the wire are first twisted with fingers, and then with pliers, tightly winding coil to coil at the junction. Place soldering twisting will provide the most reliable contact;

- the splice is closed with electrical tape or shrink tube. When operating a spliced wire in a humid room, it is necessary to apply multilayer insulation (two to three layers).

If a paired electric wire is spliced, then all operations are repeated on the second conductor with the only difference being that the connection should be shifted a few centimeters to the side for greater electrical safety. For professionals, this is called splicing "inaccurate." Typically, both spliced wires are then protected by a common layer of insulation.

Twisting wires

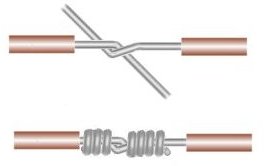

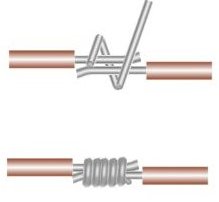

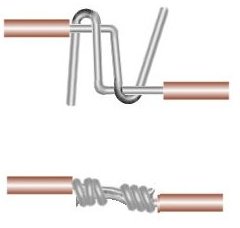

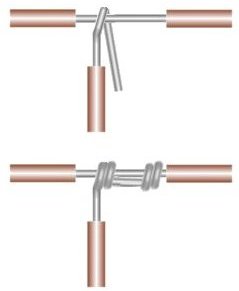

Twisting the wires can be simple, bandage and groove.

- Simple twisting is used in most cases of homework with electricity. With high-quality performance, it provides reliable and long-term contact of the circuit.

- Bandage twisting is used when connecting wires of large cross section. For this, the stripped connected sections of the spliced wires are tightly wrapped with a separate conductor of the same or smaller diameter.

- Twisting with a groove, as a rule, is used when connecting aluminum conductors, since during subsequent soldering with special solders it gives the most reliable electrical contact.

Twisted wires

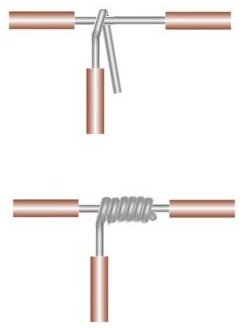

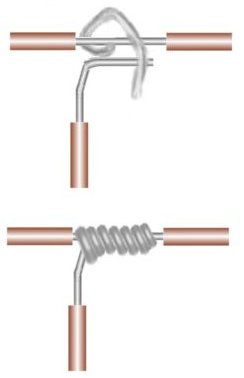

In the practice of a home master, there is often a need to make an additional branch of the electric line to connect additional consumers, install additional lighting, and so on.

This is easy to accomplish using the familiar twist technology. The preparation of the wires in this case differs only in that the stripping from insulation is carried out at the end of the branch and in the middle of the main current-carrying wire without breaking it (a gap of one and a half to two centimeters is exposed).

Simple branch twisting

Binding twisting branch

Groove Twist

When performing all types of twists, soldering the junction of the electric wires will not only improve the characteristics of the electrical contact, but also protect your home from accidental fire, which can happen with a “sparking” contact. The twisting areas of any type must be isolated to protect against accidental contact.

Compliance with electrical safety rules is mandatory when performing any work with electricity.

See also at i.electricianexp.com

: