Categories: Featured Articles » Interesting electrical news

Number of views: 1380

Comments on the article: 0

Thermoelectric material with ordered nanotubes

The world's first thermoelectric material based on ordered nanotubes was developed by a group of scientists from the Department of Functional Nanosystems and High-Temperature Materials of the National University of Science and Technology “MISiS” in collaboration with researchers from the Swedish University of Technology Lulelo and the Jena University named after Friedrich Schiller. Information on innovative development was presented in the form of an article in the journal Advanced Functional Materials.

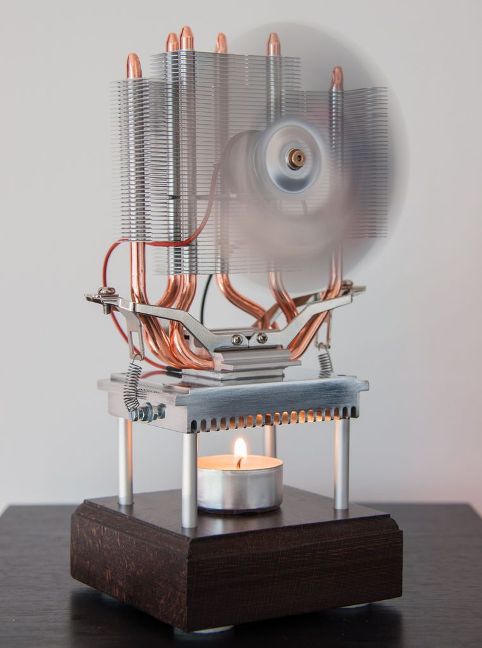

The new material has a polymer nature, so it is flexible. In addition, an additive made of nanotubes was used here, which greatly improves its electrical conductivity. The prospects for the material are colossal. In principle, it is applicable for charging mobile gadgets without the need for other traditional energy sources. A bracelet or case for a smartphone, made of new material, will allow you to charge small portable devices literally from the heat of the human body.

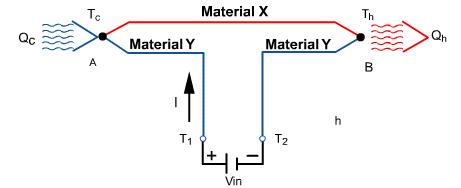

Thermoelectric materials include chemical compounds and metal alloys capable of converting heat into electrical energy in the presence of a temperature difference between parts of a sample made of such a material. If you connect conductors to an element made of this material, you can receive electrical energy through them.

Recall that the thermoelectric effect, also known as Seebeck effect, was discovered by German physicist Thomas Seebeck in 1821. And for a long time, only alloys were used as thermoelectric materials for thermoelectric generators, giving an efficiency of only about 10%. And in order to achieve maximum efficiency from such an element, it was necessary to ensure a temperature difference of hundreds of degrees, which is technically difficult to do.

In the past few years, scientists have been actively looking for alternatives to thermoelectric alloys. A solution was found - suitable polymeric materials. The polymeric materials taken as a basis allow you to create samples thermoelectric converterscapable of working even at room temperature.

In addition, most polymers are non-toxic and have low thermal conductivity, which minimizes the useless dissipation of the heat supplied to them. Unlike metal alloys, polymers have excellent flexibility, which means that, in principle, thermogenerators of any desired shape can be made from them.

The world's first sample of a modified polymer with ordered and elongated nanotubes arranged using a very promising polymer - polyethylenedioxythiophene. This polymer in itself is characterized by high electrical conductivity, in addition, the conductivity can be further enhanced by the addition of chemical inclusions in the polymer matrix of the starting material.

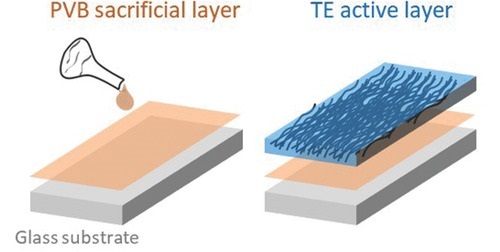

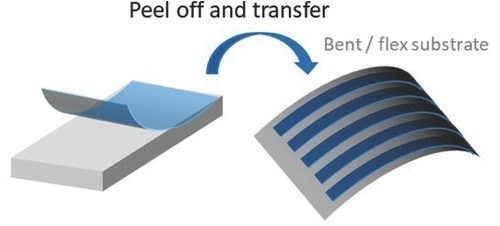

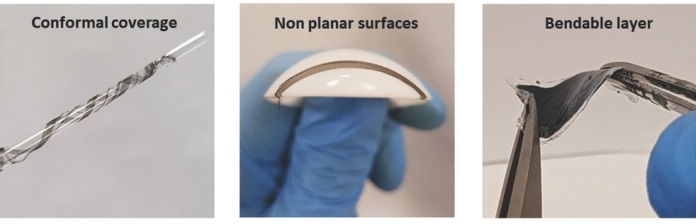

The figure above shows the manufacturing process of a composite material using a layer of polyvinyl butyral to transfer flexible curved substrates.

The following shows a composite that has been successfully transferred to three substrates of various shapes, including a curved surface and a flexible support.

The images shown show the potential use of the new material as “building blocks” for various purposes, up to using as a conformal coating for products of any shape, including bendable films and flexible substrates.

First, a vertically oriented array of carbon nanotubes was grown on a semiconductor substrate.After - the nanotubes were elongated horizontally. Then the array of nanotubes was filled with polymer.

Since when nanotubes are grown, they often accumulate, forming peculiar agglomerations, in order to eliminate such accumulations at one point, the material was subjected to subsequent processing with ethylene glycol and dimethyl sulfoxide. Upon completion of the last processing step, the specific power of the material increased by more than 4 times, that is, to approximately 92 μW * mK ^ (- 2).

One of the participants in the scientific group from the Department of Functional Nanosystems and High-Temperature Materials of NUST “MISiS”, candidate of physical and mathematical sciences Habib Yusupov claims that the obtained characteristics will allow the use of new material to create thermoelectric converters that can convert the heat of the human body (that is, work on temperature differences bodies with room temperature) into electrical energy. For example, you can create a bracelet on your hand or a cover for your phone, which can constantly power the device without the need for an additional energy source.

See also at i.electricianexp.com

: