Categories: Featured Articles » Sharing experience

Number of views: 169992

Comments on the article: 17

How to quickly remove insulation from a cable or wire

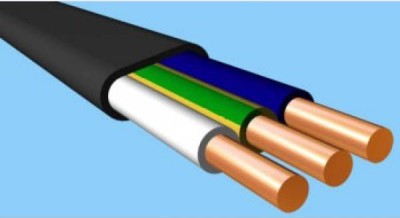

The figure shows a typical task. VVG cable 2 × 1,5mm2consisting of two single-core conductors coated with insulation and housed in a black protective sheath. How to remove the sheath and insulation from the cable so that it is fast, safe, quality and reliable? Moreover, by quality I understand here the stability of the result.

The figure shows a typical task. VVG cable 2 × 1,5mm2consisting of two single-core conductors coated with insulation and housed in a black protective sheath. How to remove the sheath and insulation from the cable so that it is fast, safe, quality and reliable? Moreover, by quality I understand here the stability of the result.

Of course, when it is possible to remove the insulation from the cable on the table, and not in a tight socket, and you need to make a couple of connections, everything can be done slowly, measured, checking every step. And if you need to make an apartment in front of plaster in a couple of days?

I tried three options for stripping the cable and stopped, as usual, on the third:

- stripping with a clerical knife;

- stripping with a special knife of the installer;

- stripping with a special device.

Stripping with a stationery knife is the easiest and most affordable way to strip wires and cables. But also the most substandard. Cable sheathing is usually done in two steps. First, a shell is cut in a circle. Then the shell is cut along the length. And then it is removed, exposing individual wires in isolation.

So, if you make an incision in a circle around the cable with an office knife, and do not calculate the force, then the insulation of the wires is easily cut, which reduces the safety of such a cable in operation.

And if it's not scary when the cable is not yet mounted (you can cut a piece and try again), then for a cable, for example, walled up in a wall, there is no room for error. When I did the wiring to my parents, I had to leave several wires so cut in the socket boxes.

Another problem is an incision along the length of the cable. Firstly, it is easy to cut along the insulation of the wire, which is even worse than its incision. Secondly, it is easy to injure a finger with a slipped blade.

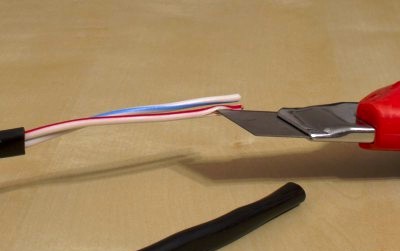

The second method is with a special mounting knife. There are a lot of models, I chose the one that crocheted. This knife is slightly more convenient than clerical. But due to the thicker blade, they can act not with the care of a surgeon, but more relaxed.

Although it is quite difficult to cut the insulation. But what makes a crochet knife convenient is cutting along the cable. The hook reliably bites into the cable sheath, and practically cannot jump out of there. Therefore, cutting along the cable is fast, safe and accurate.

But still. Such a tool does not allow for high-quality cleaning of the shell. By quality, in this context, I mean the repeatability (sameness) of the results for each shell removed. Recently I came across such a tool.

Its price varies greatly - from 600 rubles. up to 3500 rub. But in terms of quality of work, there is almost no difference. The principle of his work is as follows. The thumb is pulled by the thumb, under which the wire is pushed. A small knife peers out of the handle, rotating around its axis.

When the cable gets there, the bracket presses it against the knife. Next, wrap the tool several times around the cable. This achieves its incision.

Then, without removing the tool from the cable, you just need to pull it strongly towards the end. In this case, the knife will crank itself, and begin to cut along the shell. It remains only to remove the shell, and continue installation work.

The only inconvenience of this tool is that it is necessary to set the depth of cut of the knife with a wheel at the end under each cable. It takes me about two minutes and a piece of cable, on which I check the settings.

However, after tuning, the quality of the stripping is predictably good. I would also like to touch upon a question such as stripping insulation from conductors cleaned from the sheath.

The tool described here does a poor job of this., since it cannot “flatten” a thick cable, like many thin wires, it cuts the insulation only a little bit, pointly, below and above. This is not enough to tear and star. An attempt to apply force leads to seizure in the core as a result of "biting" the tool knives into soft copper.

And here the installer's knife described above is very effective. A crochet blade increases the radius of the knife by the wire, and you can quickly, in a fraction of a second, cut it along almost the entire diameter. Then the insulation is quickly and accurately removed. Plus, the blade hook does not allow the knife to slide off the wire.

How to strip flat cable

Prior to this, in the article, I touched on how to remove protective insulation from VVG type cables. In principle, when it comes to round VVG, it is justified to use a special tool with a bracket for stripping. But once I had to work a lot with VVG-p (flat cable). The field of this I slightly revised my preferences.

The VVG-p cable turned out to be much more convenient and practical. It is more convenient to put it under the plaster. Generally speaking, you can save a lot of time if you do not make shtrobes for plastering, but simply spread the cable along the walls, and then plaster it on top. Therefore, VVG-p in this sense is preferable. The VVG-p cable 3 × 2.5 mm2 has a thickness of only 5.3 mm. Together with the dowel-clamp - 9.3 mm. A layer of plaster, as a rule, is not less than 1.5 cm, so everything grows together.

But cutting flat cable turned out to be faster and more reliable with the hook knife. Put the cable on the board, and spend. The main thing is to put the blade immediately deeper into the insulation so that it spreads the veins and cuts between them. Surprisingly, this knife has never once cut insulation from the cores themselves.

See also at i.electricianexp.com

: