Categories: Electrician at home, Electric installation work

Number of views: 29026

Comments on the article: 0

Laying the cable through the air in the country

Summer residents who ennoble their plot, have to deal with the need to lay wires to connect lamps in the yard, electrify workshops, garages and sheds. The line can be laid underground, but then you need to dig trenches, use expensive armored cables, PND-corrugation and so on for laying. As a result, the volume and cost of the work are quite large. Another option is to lay the line through the air. In this article we will tell you how to lay a wire through the air in the country or in a country house.

In what cases is it convenient to lay the cable in the cottage by air?

To conduct light and install sockets in utility rooms in a summer cottage or in the courtyard of a private house, you need to decide how to lay the cable. We will make a reservation that any building can be in the role of an outbuilding - a barn, workshop, garage and bathhouse.

There are three options:

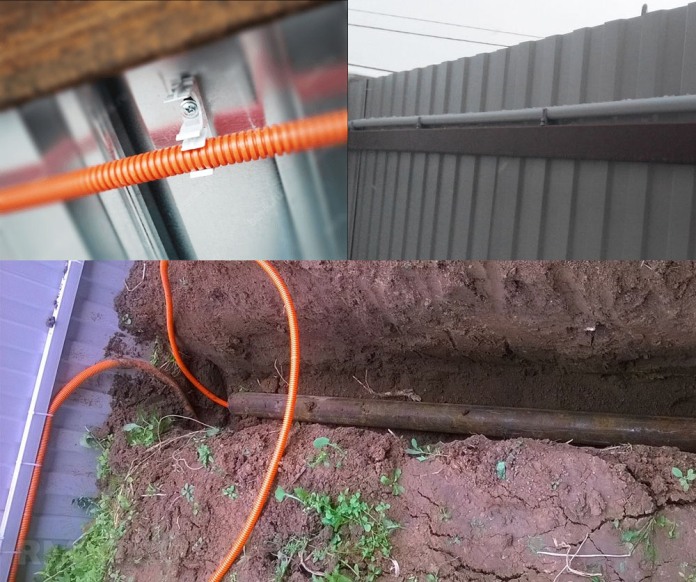

1. Laying on the fence and walls. A compromise version of the cable is laid in the corrugation or without it and is attached with plastic clamps or wall plugs to the wall surface, fence supports and other structures. The disadvantage is that not always at the outbuildings the walls are next to the fence, as a result, you still have to lay them through the air or underground.

2. Underground cable entry into the building. A good option, but the following conditions must be met: the cable must be armored, if not, then laid in a metal or polymer pipe, the laying depth should be greater than the freezing depth of the soil, when working on the site, digging trenches or pits for the foundations of new buildings is a risk damage to the line, and also do not forget about rodents that can destroy the protective shells and insulation. This is an expensive and time-consuming way to lay an electric line.

3. Laying the cable through the air. Its advantages are that you do not need to dig a trench, in the worst case you will have to install a support, usually a metal pipe or corner is used as a support. If the distance does not exceed 25 meters (I will describe in more detail my opinion on this subject below). The disadvantage is that the line must be protected from damage due to environmental influences.

Key Features and Problems

When laying wires and cables outdoors by air, the following factors must be considered:

-

Increased temperature when laying under the sun;

-

Ultraviolet when hit by direct solar is best;

-

Low temperatures and ice in winter.

All this leads to a deterioration of the state of insulation, its cracking, what is the danger of such a development of events? If the insulation is damaged, leaks can occur, which means that you can be shocked by touching the supports on which the line will be fixed, as well as short-circuiting with the corresponding consequences (knocking out machines, burning out connections, and fires in the wiring).

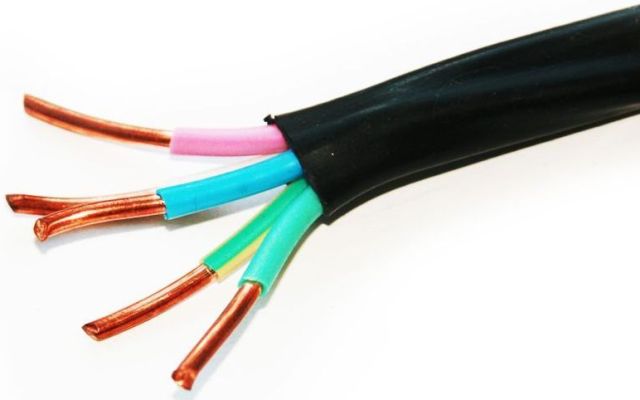

The listed factors are especially dangerous for vinyl insulated cables. These include a variety of brands such as PVA, ShVVP, VVG. Yes, and rubber insulation deteriorates under the influence of ultraviolet radiation. How to protect wires from the sun? To do this, use pipes, corrugations and other products. Laying methods we will consider below.

In addition to harmful natural influences, it should be remembered that the electric line must be protected by a separate circuit breaker, this is necessary so that in case of damage to the cable there is no fire. And also to maintain the integrity of the line if overload occurs. In the building that you will electrify, you also need to install circuit breakers and RCD.

Material selection

Airways that go through the streets are laid using SIP wire - its marking stands for “Self-Supporting Insulated Wire”. Its design provides for laying over the air without the use of additional load-bearing cables.

However, most of the electrical wiring in modern country houses is copper, which means we will use a copper conductor on the overhead line. It has several advantages:

-

It’s more convenient to connect. Copper tolerates connections due to the fact that it is denser than aluminum and less prone to deformations as a result of twisting and the use of terminal blocks.

-

Compared to aluminum wires of the same cross section, copper conductors withstand 1.5 times more current.

It may seem that this is an insignificant advantage, because no one bothers to buy thick aluminum cables or wires. However, keep in mind that when laying the line in a garage or a barn where you are going to connect powerful appliances, for example, a welding machine, you will have to lay an aluminum cable of 6-10 square meters. mm, depending on the load, while using copper you will have enough 2.5-4 sq. mm.

It should be remembered that the thicker the cable, the more significant problems can arise when it is connected or clamped in terminal blocks of machines and other devices. Therefore, it is rational to use the currently popular VVG-ng-LS cable.

To protect the cable from ultraviolet radiation, you must use corrugation. If this is not done, then the product life declared by the manufacturer will be reduced significantly. therefore quite acceptable gasket "Temporary house" and construction lines and without protection.

When using the widespread gray PVC corrugation, you need to take into account the fact that it is not resistant to ultraviolet and frost, when it is used outdoors, it will crack. But there is another type of corrugation - polyethylene or PND-corrugation. Usually sold in black or blue.

We examined the properties in more detail, and described the installation features of corrugated pipes for electrical wiring in the article Errors in wiring in corrugation

When choosing the diameter of the corrugation pipe for the cable, you must take into account the diameter of the cable and the corrugation itself. According to PUE 2.1.61, when laying wiring in pipes, the filling of the pipe should be no more than 35% of the cross section in the light.

How to choose the correct diameter of the corrugation?

Suppose we are going to lay a cable VVG-ng-LS, the outer diameter of the cable is 11.2 square meters. mm, in the PND-corrugation 40 mm is the outer diameter, and the inner diameter is 31.5.

Let's calculate the corrugation area:

Soffers = (3.14 * 31.52) / 4 = 778.9 sq. mm

Since it can be filled by 35%, the total cable cross-sectional area should be no more than:

778,9*0,35=272,6

The cross-sectional area of the cable is:

S cable = (3.14 * 11.22) / 4 = 98.5 sq. mm

Then you can lay cables no more than:

272.6 / 98.5 = 2.76 pcs.

That is, such a corrugation is enough for two cables of this section. It is important to comply with the requirements of the PUE.

Cable routing on a cable

The easiest way to lay the cable through the air in the country - use a cable. The modern range of hardware stores allows you to choose different metal cables, for example galvanized steel. A cable with a diameter of 4-5 mm is suitable. It will perform a bearing function.

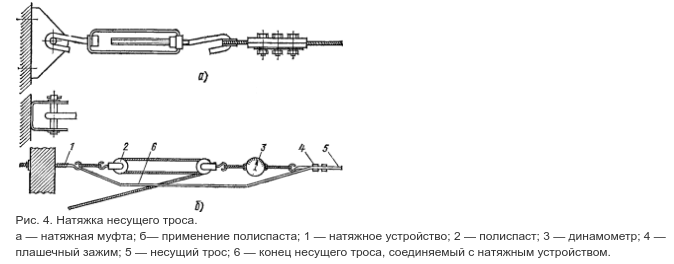

The cable is pulled with hooks, lanyards, chain hoists or other products for tensioning cables and ropes, you can also use tension clamps for self-supporting insulated wire, although the article deals with laying copper cable through the air, but this product also works.

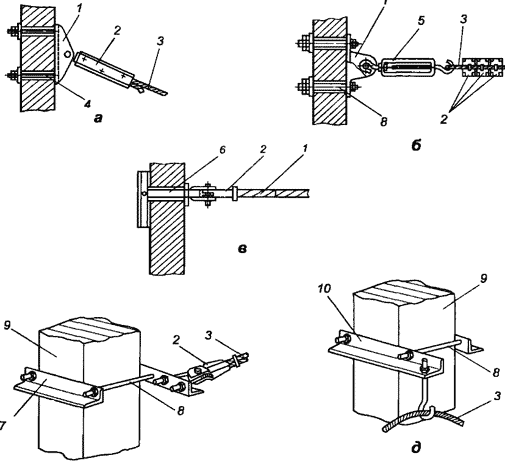

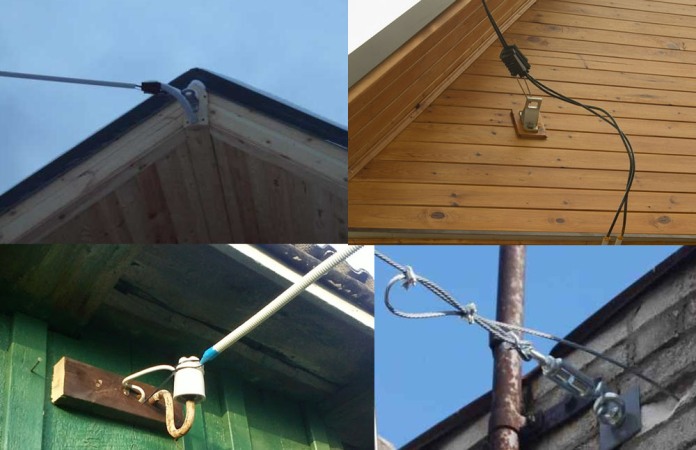

Such tensioners are attached to the wall using anchor rings, hooks or homemade plates with fastening.

Installation of anchors on the wall and girths on the column:

In the picture: a, b - on the wall with bolt-on; in - on a wall with a folding lath; g, d - on the column with heels 1 — anchor; 2 - cable clamp; 3 - bearing cable; 4 - a bolt; 5 - tension coupling; 6 - an anchor with a folding lath; 7 - terminal girth, 8 - hairpin; 9 - column; 10 - intermediate girth.

How to pull the cable to the house to the barn or garage? If the distance is small - it is pulled from the house to the building using the aforementioned tensioners.But I believe that here you can apply the clause PUE 2.4.12 on the maximum length of the branch of the self-supporting insulated wire for entering the house from the power transmission line. It says that the maximum branch length for an SIP wire with a cross-sectional area of conductors of 16 square mm, although this is not entirely correct.

But it will be more correct to calculate the strength and maximum mechanical load that the steel cable can withstand, and you can follow sound logic and imagine how you will stretch a steel string 50 meters long between buildings so that it does not play in the wind in a tense state.

Therefore, I believe that the optimal distance for aerial wire laying in the yard of a summer house or private house is 20-25 meters. If the distance is greater, you need to install the supports and pull the cable using the same tensioners as shown above on them, the incoming cable and the next cable from the support to the outbuilding. In this case, the cable should not be pressed firmly against the support; for this, make a loop as shown in the figure below.

In practice, proceed from the specific conditions and circumstances in your yard.

After the cable is pulled, pull the cable into the corrugation, it has a probe for this, by the way, the video below shows a quick and convenient way to do this.

Next, the cable in the corrugation is attached to the cable, it is more convenient to do this with plastic clamps. Actually, this is where the laying process ends.

See also at i.electricianexp.com

: