Categories: Safety precautions

Number of views: 23047

Comments on the article: 1

Safety when working with tools: how to avoid injuries and maintain health

A modern person uses a mass of various devices and tools that not only make life easier, but pose a certain risk to health.

Manufacturers take into account the possibility of injury, apply design solutions that increase safety of use, install several degrees of protection on their products, but there are always people who manage to violate the rules of operation and as a result receive various injuries.

A few tips outlined in this article should help you maintain your health in the event of unforeseen situations during home repairs.

Knowledge of safety rules

The hope of "maybe", characteristic of most people, can create a sad situation. As soon as a new, unfamiliar tool is in your hands, be sure to understand the rules for safe working with it. Only after that it is possible to study its governing bodies and begin to check them in business.

Even if you have long mastered working with electric, carpentry or other tools on an intuitive level, then in this case, read the rules for their safe use. After all, they are compiled on the basis of statistics on accidents, and knowledge is not superfluous.

Workplace preparation

The presence of free space for hand movements, the absence of foreign objects that distract the attention of the worker reduce the risks of getting herbs. Often, to restore order, it is enough to make only a few movements. Many good masters have developed a rule to keep at hand only the necessary tool and immediately remove all unnecessary.

This is especially true when working at height. In addition, when rising to a chair or stool, care should be taken about their stability.

Falls from small ladders are most often associated with the haste of their installation, the lack of thought of the place, and inattention.

Workspace selection

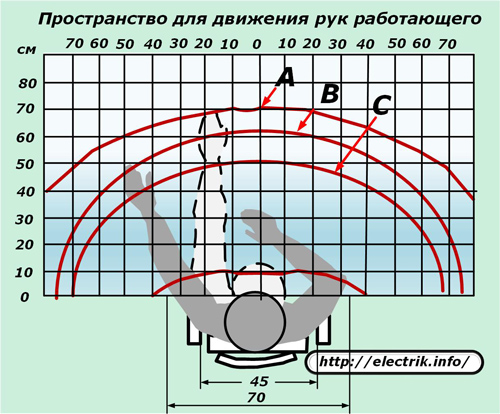

The optimal distance from the person to the surface to be treated is determined by the length of the arm and averages about 50 cm (curve C). The permissible distance to the object is 60 cm (B), and the maximum is 70 (A).

In the vertical position, it is convenient to operate with objects placed at a height of 1.0 ÷ 1.6 meters. Above and below are areas of moderate difficulty and inconvenient work.

Tool check

Before you begin, carry out a quick inspection of what you will use for danger of personal injury. Poorly set hammers, axes, sledgehammers can fly off the handles and cause a lot of trouble. Scuffs and nicks in the handles of a chisel, file, chisel, saws can injure the skin.

Electrified tool

In electrical appliances, it is necessary to carefully examine the surface insulating layer, pay attention to the quality of the plug, cable entry tube into the housing, controls, holders, fastening of the working bodies.

Cracks in the housing are not allowed. The ventilation openings must be free.

Do not work with an electrified tool if any defects are identified on it before they are removed.

Knife selection

The most common injury for home craftsmen is cuts. They often come from a wrong knife.

To perform electrical work, it is better to use factory special models, rather than home-made and especially economic ones. The convenient, reliable handle should hold well in the palm of your hand and have a protective emphasis.A short and durable blade with angular sharpening allows you to well cut cable ends and wires, has a minimum risk of injury.

During storage, any knife should be in its sheath. This keeps the blade sharpened while protecting it from cuts.

Awl, chisel, chisel, scissors, saws

They relate to stabbing and cutting tools, have sharp edges that can easily injure a person if mistreated.

This tool must be kept in special containers, and when working with it, point the blade tips from the body, and not towards yourself.

Clothes and shoes

At energy enterprises, workers are given dense overalls or jackets and trousers made of cotton fabrics. They pass air well, retain heat and protect the human body from accidental effects of a mechanical tool. The high dielectric properties of such dry materials used to be widely used to cover the outer layer of cable insulation in household appliances.

When doing homework, you should consider this experience. Using clothes, pay attention to the fact that it should not hamper movement and have hanging ends that can fall into rotating parts or simply cling to surrounding objects.

Our ancestors paid attention to this issue even during the mass introduction of mechanisms. They were displayed on Soviet-era safety posters.

It is also necessary to protect the hair on the head from the possibility of capture by rotating parts.

With modern tools, the cases of all mechanisms are made with better protection than before, but the risks of injury still remain. Each employee must worry about their own safety, pay attention.

The reason for the fall during work is most often shoes with slippery soles, not designed for difficult operating conditions.

Work gloves or gloves, goggles and masks, respirators and headphones protect the home craftsman from mechanical damage. If they are used in a timely manner for their intended purpose, the number of injuries will drop sharply.

Manufacturing jobs

Steady position

A correctly selected pose of a working person is considered one of the main safety rules. This should not be neglected.

Performing any mechanical action, you must first take a stable position, eliminating accidental falls, slippage, rocking. This is facilitated by legs spaced shoulder-width apart, a half-bent back, and the position of the hands providing good balance.

Even accidental impacts from a hammer escaping from a hand during impact, jamming of a drill due to a skew of a drill, “blows of a grinder” will be smoothed by the reflex actions of muscles in a stable, correct position.

Surface treatment

Hand tool

All details that need to grind, trim, saw, drill must be securely fixed before work. To do this, there are various vices, machines, presses, mounts, pads.

When working with cutting and stabbing tools, monitor the position of your fingers, never place them on the edges of the handles and especially the blades. The palm should fit the handle tightly outside the special stops. The blade must be held so that it is clearly visible.

If large swings are necessary with a hammer, ax, sledgehammer, always mentally track the zone and plane of movement of the tool. There should not be any foreign objects, let alone people, animals.

For example, when chopping wood, an ax can accidentally slip out of its hands and fly out, causing harm. Therefore, the legs are always kept shoulder width apart, not shifted. If two lumberjacks work, then they are never located opposite to each other.

Safe work with home tools is only possible in good light.Attempts to fix something during poor visibility (dimming, blinding light) can result in injury.

Power tool

Often people get cuts when drilling small parts that they hold in their hands or using pliers. The design of the drill is such that after the start of exit from the metal layer there is an increased capture of the mass of material by the cutting edge. Due to this, the effect of torque sharply increases on the part. He tears the workpiece out of his hands. Even the holding force with the pliers is not always enough.

As a result, on the drill, we rotate with great speed, it turns out to wear a small metal part, which easily destroys all objects that are in the way of its movement. If it was held by a hand, then lacerations of fingers were provided.

Working with a drill puncher, grinder, mentally trace the path of the cutting tool with an electric circulation saw and always set a strict direction for its movement, do not exceed the required pressing force. Any change in angular displacement is associated with the risk of jamming and breaking of the drill, destruction of the cutting wheel, and the expansion of fragments in the plane of rotation.

Special screens are used to protect against falling apart fragments of an abrasive disk. Their main drawback is the limitation of the visibility of the processing site. Because of this, some of the people thoughtlessly remove them, putting their health at unnecessary risk.

But even the protective cover on the grinder cannot fulfill its protective function from getting injured by the worker with reflected fragments, which changed their direction of flight when meeting with nearby objects.

Most modern power tools have two control functions that require:

1. Constantly pressing the power button with your fingers;

2. Blocking the shutdown function by the latching switch.

The second opportunity is made for the convenience of users when transferring the tool to a long operating mode, but it affects the safety of operation. After all, if an unforeseen situation arose, for example, an electric shock or a fall, then a person instinctively throws the instrument to the side by the action of muscular reflexes. In this case, the power button will be released and the device is de-energized, stopped.

When the stop function is blocked, the discarded tool will rotate and work, presenting a source of danger that needs to be stopped quickly, but you won’t be able to immediately figure out how. Therefore, this opportunity is used only in the case of reliable stationary fixing of the tool and convenient control.

Hasty replacement of the working tool of an electric tool can also cause injuries. For example, individual craftsmen often have to change drills of various diameters in drills, and they perform this operation when the cable is connected to the outlet.

One has only to accidentally touch the power button, as the electric motor turns on and injury is ensured. Safety rules prohibit such actions.

The power cord of a portable working electric saw, an electric trimmer mowing grass, constantly moves along the ground, may be damaged by the cutting body. To prevent this from happening, it is always necessary to position it at the back and during turns, control its location, avoid getting on hot roads and under heavy or cutting objects.

Most models of household electric tools are not intended for use in damp rooms or outdoors in rainy, cloudy weather. For such conditions create special waterproof enclosures.

If there is a feeling that the instrument is “beating current”, then you must immediately stop working, turn off the power, find out the cause of the malfunction. And so that this does not happen at all, then use when connecting circuit breakers, which eliminate the arising short circuit currents and residual current devices, responding to load leaks.

Completion of work

Imagine a picture: the owner finished the hard work with an electric tool and sat down to rest aside. And at this time, the children started the game, having begun to imitate their father ... We will not continue to fantasize: after all, immediately removing all dangerous objects from the workplace in order to exclude injury to other people is a sacred duty of a home master, which cannot be neglected.

Any work is considered completed only when all the potential risks of harming human health have been completely removed and eliminated. And this means that open cases and covers must be closed, and the tool laid in its place of storage.

See also at i.electricianexp.com

: