Categories: Featured Articles » Interesting electrical news

Number of views: 3444

Comments on the article: 2

What are the innovations in the market for electricity metering solutions?

Accounting for electric energy may open up new opportunities for improving the efficiency of the enterprise. At the same time, modern solutions in this matter, integrated with advanced software, can not only transmit accurate data for each unit of energy consumption (from one machine to entire production lines and workshops), but even warn of possible equipment malfunctions, predicting the most possible breakdowns and failure.

This and not only distinguishes modern electricity metering systems from traditional ones, which we will try to understand in this article.

Typically, the electricity metering system is represented by meters that directly capture data on electricity consumption, as well as data transmission elements and their further processing on the computer of the main power engineer.

The disadvantage of such a system is that there are many manufacturers of meters, data transmission devices, programmers and software options on the market that integrators are trying to “combine” with the companies. Sometimes it happens that the protocols are incompatible, and the controllers require separate firmware, etc.

All this takes time, and most importantly, the resources that the customer has to pay. Therefore, many companies, when it becomes a question of modernizing the electricity metering system at an enterprise, study this issue with a great deal of fear, lay large budgets and implementation timelines, as they will be forced to wallow in the long and difficult process of installing a technical accounting system.

However, recently this situation has begun to change. There are more and more solutions on the market that differ in their completeness when the software and hardware are produced by one company, which reduces the risks of their incorrect pairing. At the same time, there are simpler energy metering devices with already integrated data transmission and storage systems. One such solution is the Panoramic Power wireless monitoring system.designed and manufactured by the company of the same name in Israel.

Apparently, the developers decided to take into account all the problems voiced, so they not only developed the most advanced software for monitoring electricity in the market, in our opinion, but also created unique miniature wireless sensors that are installed without breaking the insulation and breaking the cable. At the same time, the smallest sensor weighs only 23 grams.

Figure 1 - The smallest PAN sensor in the Panoramic Power metering system

To create such a minimum size, the developers decided to make sensors without batteries, and take this same power from the surface of the conductor, i.e. energize the entire sensor from the electromagnetic field.

As a result, it allowed to reduce the size, remove numerous wires, get away from batteries and reduce the time for installation and maintenance. As a result, dozens of sensors (control points) can be accommodated in one compact electrical cabinet instead of 2-3 conventional electricity meters.

Fig. 2 - Photo of installed PAN series sensors in an electrical cabinet

After installing the sensors, all energy consumption data is sent either to the cloud software or to the customer’s software products.

Fig. 3 - Block diagram of the Panoramic Power wireless technical power metering system

Working with data allows you to get instant results, because Data from the sensors arrives every 10 seconds, which allows real-time monitoring of the entire situation at your enterprise.

Here are just some of the advantages of using a modern automated wireless system for technical accounting of electricity:

1. Reducing the cost of paying for electricity by automatically monitoring the operation of the equipment and proper planning of the maximum load. Profit is achieved through the rational use and reduction of unproductive losses of electricity.

2. Reducing the cost of maintenance and overhaul by setting up notifications about the atypical operation of equipment and predicting breakdowns.

3. Improving staff productivity through remote monitoring of compliance with equipment operating procedures (equipment on / off modes, equipment downtime).

4. Identification of “invisible” losses and unproductive energy costs due to the full internal electricity metering and data analysis using the built-in automatic weekly / monthly / quarterly reports.

5. Optimization of energy consumption and consumption through the use of optimal management strategies.

The results of the introduction of such systems are on different types of objects. Here is one of the cases that shows what results can be achieved with high-quality work with the energy monitoring system.

The introduction of the Panoramic Power wireless energy metering system in the woodworking industry made it possible to detect a breakdown of one of the drying chamber engines, which led to an increase in the drying time of wood. By eliminating the problems, it was possible to save more than 1,500,000 rubles. in year.

Thanks to the analysis of the data and the capabilities of the powerful cloud software of the energy monitoring monitoring system, more efficient engines were detailed and the operating modes of the dryers were adjusted taking into account energy costs and drying time. This led to a reduction in the cost of drying wood by 38% or savings of more than 125,000 rubles. per month, which also reduced the cost of production.

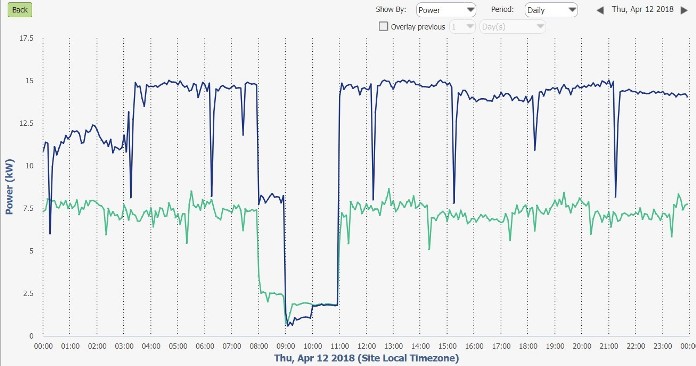

Fig. 4 - Comparative analysis of the operating mode and electricity consumption of drying chambers

In addition, the task was to control the power consumption of the enterprise in the morning. A power limit was determined that should not be exceeded. We set up several notifications that worked when approaching the limits. This made it possible to turn off powerful equipment without disrupting technological processes, and to reduce power consumption, which led to savings of more than 150,000 rubles. in year.

Fig. 5 - The use of energy monitoring system allowed to begin to control the power consumption of the enterprise

The result of the introduction of a wireless energy monitoring system at the enterprise was not only the solution of its primary tasks, such as metering electric power in workshops, but also the control of equipment operation, its operability, the control of personnel and production processes.

Thus, the main direction of reducing electricity costs and increasing the efficiency of production and use of electric energy is the widespread introduction of information technologies and automation tools, such as an automated wireless electricity metering system, which allows you to get a complete picture of energy consumption for each piece of equipment.

Below, you can see how easy the Panoramic Power wireless solution is.

See also at i.electricianexp.com

: