Categories: Sockets and switches, Electric installation work

Number of views: 6250

Comments on the article: 0

How to drill a wall outlet for a wall outlet

Work as an electrician is not always assembling and repairing circuits and laying cables. To lay a line, install sockets, hang fixtures, you need to properly make holes or hollow out a recess. To do this, you need to know the main types of drills and the features of their use. In this article, we will look at how to drill a hole in concrete, wooden walls and metal surfaces.

Types of power tools for drilling

In everyday life for the main construction works use:

-

Screwdrivers;

-

Drills

-

Impact drills;

-

Hammers.

Screwdriver - This is a small device designed to wrap screws and self-tapping screws in non-solid materials. They are also suitable for drilling drywall chipboard, plywood, wood and its other derivatives. Suitable for drilling not too thick metal. They are wireless and wired.

The characteristics of cordless screwdrivers usually do not indicate power, but the voltage of the battery, and often, the higher it is, the more power and torque the device has, but there are exceptions. Whereas in the characteristics of wire screwdrivers they indicate exactly the power, but they work directly from the 220V network.

The main distinguishing feature of a screwdriver from a drill is the presence of a ratchet (torque adjustment clutch). A ratchet in screwdrivers is a mechanism that limits the torque on the chuck. This is necessary so as not to tear the slots in the heads of screws and screws and not to damage the material.

Also, in screwdrivers, in addition to adjusting the revolutions by the depth of pressing the trigger button (the harder and deeper you press, the faster the cartridge rotates), there is also a mechanical speed switch. Engaging the other gears of the gearbox and lowering the speed is not “electrically”, but “mechanically”.

Thus, at a lower speed you get more torque, which cannot be achieved if you simply set the rev limiter to the low limit on the trigger and pull the trigger quite a bit (if the revolutions are adjusted on your screwdriver by the depth of the trigger).

Conventional Hammerless Drill, differs from a wire screwdriver in that they do not install a ratchet in the drill to limit torque, and there is no speed switch. The power of the drill can be as high as 500 watts - manual miniature ones are similar to screwdrivers, and with a power of 2 kW or more.

Cartridges come in two types - keyless and keyless. On screwdrivers, they are mainly keyless.

Hammer drill equipped with a shock mechanism. It is based on two friction wheels (ratchet wheels) with teeth on adjacent sides. It can work both in simple drilling mode and in drilling mode with impact.

The impact force is largely determined by the axial load on the drill (the force with which you put pressure on the tool when drilling). The device is suitable for drilling all common wall materials. Concrete drills slowly, works better on bricks and cinder blocks, you won’t be able to make a strob, but in most cases it’s easy to hang a picture, and if you can, then do it hole for the socket.

This video demonstrates the principle of the impact drill:

Hammer drill - This is a powerful device for drilling and drilling. It can drill without a punch, with a punch, and work only in shock mode, like a jackhammer. If a percussion drill drills and knocks lightly, then the perforator actually chisels the wall (see - How to choose the right punch).

In it, a blow is already formed not due to the friction of two discs with teeth, but with the help of a shock mechanism, the principle of which you can see below.

One of the main features of the punch is a method of securing a snap - drills, crowns and other nozzles.

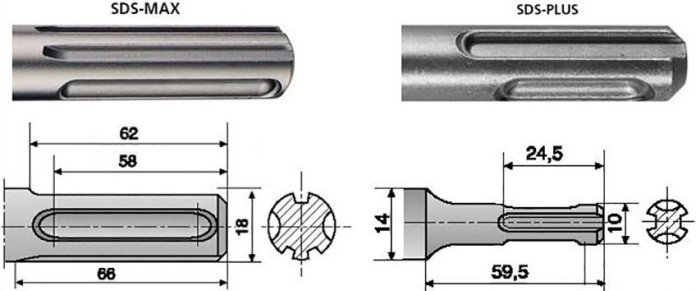

For this, it is not a cam chuck in which the drill was clamped by rotating its outer cage that is used, but the so-called quick-detachable SDS chucks, developed by Bosch, they come in different modifications, pay attention to buying in the store.

You can also insert ordinary equipment without a shank, from drills, into the puncher, but for this, adapters such as the one shown below are used.

You can’t clearly say what is best for the house - a drill or a puncher. Probably both. These are different tools for different types of work - How is a hammer drill different from a drill

What are drills?

There are a large number of drills and each of them is created for certain types of work.

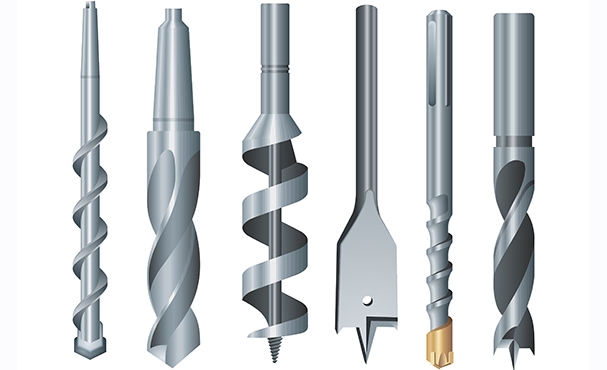

Spiral or screw drills are the most common type of drill. This name was given due to the characteristic shape of the working part - it is made in the form of a screw, twisted grooves go along the working fluid. This design allows you to remove chips from the hole during the drilling process. There are various types - for metal, concrete and wood. They differ in screw pitch, sharpening angle, the presence of brazing from carbide materials or a centering spike. The figure below depicts drill bits for metal.

Pen drills - used to make a hole of large diameter, or to make a recess by not drilling the surface to the end.

Crowned or ring drills, in the people they are called simply "crown". For wood, they are thin-walled, on the working surface of the teeth are like a hacksaw, and for concrete and other hard materials they use carbide-tipped or diamond-coated crowns.

"Ballerinas" or as they are also called "circular drills" - outwardly resemble compasses. They are used for drilling different holes, an interesting feature is that using one such drill you can make holes of different diameters, since the cutting part moves along the material being processed.

How to drill different materials

To begin with, the holes in wooden walls, ceilings, and other various details, oddly enough, make a drill or a crown on wood.

In many cases, with infrequent work, a drill for metal is suitable, especially when drilling holes of small diameter, for example, for a self-tapping screw. However, as has been said, wood drills differ from metal drills by the presence of a tip at the end. This is necessary to center the drill and the hole turned out smoother. For drywall drilling - the choice of drill is similar.

Holes in concrete, cinder block, and brick are made with drills or crowns with victorious (in other words, hard-alloy) solders in the form of teeth or diamond dusting. By the way, concrete drills with victorious soldering you can see at the bottom of the next figure.

They are also suitable for modern popular building blocks, such as foam concrete, aerated concrete and the like. During long-term drilling, especially with a percussion drill (with its help, the process is always slower than with a perforator), it is necessary to cool the drill - to lower it into the water periodically. So it will last longer without sharpening, and carbide brazing will remain intact.

The video demonstrates drilling a hole for a socket with a diamond crown in a concrete wall:

When working, the drilled place and the crown (diamond) can be moistened. You can do this with a spray gun (such as spraying flowers) or in another way. Diamond and tungsten carbide crowns work without impact, in the simple drilling mode, in this case it is possible to use not a perforator, but a powerful electric drill. Winning crowns work when drilling with a blow, are well suited for a perforator. In this case, you need to drill “dry”, that is, without cooling with water.

For tile or glass, a drill is used, in which the working part resembles an arrowhead, it is often called a spear-shaped drill, and in the store you can simply say “tile / glass drill”. For round holes - diamond tungsten carbide crowns or “ballerinas”.

But be careful when drilling holes in porcelain tiles. On the package of crowns for her, the possibility of working with this material is usually indicated. Consider the fact that relatively small holes - 7-8 mm in the tile can be made not only with a drill, but also with a small diameter crown, as shown above.

This video shows the main types of drills and techniques for working with them on different materials:

We end the features of using different drills and crowns, share your experiences in the comments!

See also: Features of mounting sockets and switches on various surfaces

See also at i.electricianexp.com

: