Categories: Featured Articles » About electricians and not only

Number of views: 120506

Comments on the article: 11

Profession Fitter Instrumentation

At the mere mention of the word "locksmith" in the mind there is a person who performs mainly mechanical work. In his hands you can see a screwdriver, file, wrench and even a sledgehammer. All these tools are also used by the instrumentation and automation fitter, since the equipment that has to be repaired, adjusted and serviced is the most diverse.

At the mere mention of the word "locksmith" in the mind there is a person who performs mainly mechanical work. In his hands you can see a screwdriver, file, wrench and even a sledgehammer. All these tools are also used by the instrumentation and automation fitter, since the equipment that has to be repaired, adjusted and serviced is the most diverse.

Here you can meet the thinnest, almost hourly mechanisms, heating furnaces, water valves, injection mechanisms of large injection molding machines or frequency-controlled electric drives. Therefore, the instrument requires the most diverse: from microscopic screwdrivers to pipe wrenches of the latest number.

When carrying out various communication lines, for example, to connect sensors, a sledgehammer, and even scrap, is often used. Without this tool, a hole in a brick, especially a concrete wall, is absolutely impossible to make. True, recently these prehistoric tools have been replaced by modern electrified rotary hammers, “grinders” and other tools. But, nevertheless, sometimes you have to use a crowbar and a sledgehammer.

It often happens that in a mechanism some part made of sheet metal simply breaks. To restore this part must be replaced, but if there is no spare, then if possible make a new one. It is enough for this to pick up a hammer, chisel, file, can even drill with a drill and whip up at least a temporary replacement, for which at least sketch a sketch of a future part with a pencil by hand. If the instrument technician has such skills, then he simply has no price!

Ability to work with hammers and screwdrivers is not all that should be able to true instrumentation engineer. First of all, he must know the basic laws of electrical engineering and have an electrical safety group of at least III, know how a transistor, logical or analog microcircuit. Knowledge of microcontroller technology is also useful, and even if you have programming skills of microcontrollers, then this is very good, even excellent.

Various Instrumentation and Instrumentation It is impossible to imagine without the use of electrical and electronic circuits. Therefore, in addition to the plumbing tool kit, the instrumentation and control fitter must have a perfect knowledge of the multimeter, know how to measure voltages, currents and resistances in electrical circuits. After all, electricity is not a mechanic where you can see with the naked eye that this part has worn out. Here you can find the fault only with the help of devices.

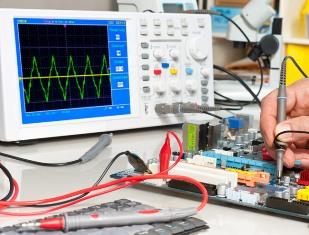

But often only a multimeter can not do. In order to visually see what is happening in the circuit, whether the signal passes, what is its shape or is it completely gone, you have to use an electronic oscilloscope. Despite the apparent complexity of this versatile device, using it is quite simple. There would be a device, and there would be practice, the rest will come with time.

It is best if it is a modern small-sized oscilloscope. True, its price is quite high, but the ease of use is certain. First of all, these are small dimensions, the presence of memory that allows you to observe even non-periodic signals, as well as the ability to connect such a device to a computer. But, nevertheless, still have to use the good old electron-beam oscilloscopes, allowing any measurements.

That's how smoothly we came to the fact that in the arsenal of the instrumentation and control workshop there should certainly be, albeit not the “coolest” gaming computer, but not the oldest.First of all, various electrotechnical calculation programs, graphic circuit editors, and programs for developing printed circuit boards should easily “go” to the computer. It should also provide for the possibility, if not development, then at least of viewing engineering drawings.

A modern instrumentation and control specialist should have a very wide range of knowledge and skills. It is not without reason that in many instructions for various devices there is a line: “Repair and maintenance of the device should be carried out by specially trained personnel.” To obtain this specific knowledge, there are various continuing education courses.

For example, in order to become a Kipyan for work in modern automated boiler rooms. Indeed, in the boiler room there are various gas analyzers, devices for measuring the temperature and pressure of water, electronic control units for boilers. The work is very responsible, therefore, without special education and certification, the entrance to the boiler room is simply closed.

Knowledge of the device of individual sensors and devices that are used in the equipment, of course, is necessary. But this knowledge alone is not enough. It is required to know the technical processes themselves in which these sensors are used. Indeed, in order to determine whether, for example, a manometer, thermometer or flow meter correctly displays, one must know to what extent the pressure, temperature, or flow rate of a liquid or gas can vary.

Modern electronic equipment is reliable enough; it is not necessary to repair it very often. Manufacturers, as a rule, “forget” to attach electrical circuits of devices, do not want to share their secrets. But on several pages, or even a separate little book, they apply instructions for programming the operation of the device.

All this is done by pressing the buttons on the control panel, and these settings are made by the employees of the instrumentation and automation department. In some cases, equipment is configured using a laptop with appropriate software. These manipulations are also carried out by the mechanic of instrumentation and automation.

What a control engineer must know and be able to

The list of all this is so great that more than one article would be needed, and not even two. You can learn more about the requirements for the profession in a regulatory document "Profession 220703.02 - Locksmith for Instrumentation and Automation (Instrumentation)", which provides a fairly long list of equipment that can be met by an instrumentation and automation engineer, as well as what he should know and be able to. True, this document is so ancient that almost nothing is said about electronic technology, but the repair of arithmometers and typewriters of all systems is proposed. But in general, you can get a general impression of the requirements for a fitter of instrumentation and automation.

Workplace of a fitter

First of all, the presence of an electrical installation table, equipped with adjustable sources of constant and alternating voltage. There should be a soldering iron, even better Soldering Station. Since the work is small and painstaking, lighting should be appropriate. More often this is achieved with the help of local lamps on each table.

For locksmith work, of course, you will need a workbench with a set of locksmith tools: screwdrivers, wrenches, files, drills, etc. It’s good if there is a drilling and at least a small lathe in the workshop. Such equipment will once again not go somewhere and ask for something.

In the workshop there must be a place to store technical documentation for the equipment being serviced. These are, as a rule, technical data sheets, electrical circuits, all kinds of repair, maintenance, and preventive maintenance logs on entrusted equipment.

In modern conditions, most of the technical literature - reference books, books, technical journals are available only in electronic form, stored on a computer or located on the Internet.Therefore, for a computer, a place must be found, however, like the computer itself.

According to sanitary standards, in the instrumentation and control workshop per person should be at least 4.5 square meters. The temperature in the room should be 20 ± 2 degrees Celsius. When carrying out soldering work, exhaust ventilation is also required. Unfortunately, these requirements are not always met.

In addition to the workplace in the workshop with a table and chair, Kipovtsy have to perform work directly in those places where this equipment is installed. Then the workplace will be the room where the electric cabinet is installed, or even some well with sensors or the roof of the building where the antenna is installed. For such work, you should have a small portable tool kit: just take the suitcase and go.

Who can work as a fitter

The presence of a technical education in the specified profile is not yet the basis for making a good fitter of instrumentation and automation from a person. However, the above can rightly be applied to any profession. An important role is played by a set of personal qualities: the ability to work in a team or alone, make the right decisions with a lack of time and information. Also, the ability to concentrate in various interference conditions, good memory, technical mentality.

Naturally, when applying for a job, a person undergoes a medical commission. Health requirements are about the same as when working on electrical installations: you do not have to be a candidate for cosmonauts or pilots. Everything is determined by the requirements of labor protection rules. But at the same time, there are a number of diseases with which the work of instrumentation and automation fitter is contraindicated.

First of all, these are diseases associated with loss of consciousness or spatial coordination, a disease of the organs of hearing and vision, organs of the cardiovascular system. Hand tremors (tremors) and diseases of the musculoskeletal system are completely unacceptable. In this case, you should think about choosing a different profession, a different field of activity.

Where to learn how to do instrumentation and automation

Special education in the profession of instrumentation engineer can be obtained at various educational institutions. Previously, they were called vocational technical schools of vocational schools (some are still called), now these are technical colleges, and some even lyceums. They exist in many cities of the CIS, their detailed list with addresses and directions is easy to find on the Internet.

But, even if there is no such educational institution nearby, there is no need to despair. An education obtained at an electromechanical college or college, as well as a radio technical college, is quite suitable. After all, it is no secret to anyone that many successfully work in completely the wrong profession in which they studied.

After training, all educational institutions graduate specialists at level 2, with a maximum of 3 categories. The tariff grid of instrumentation and automation technicians provides for grades two to eight, which indicates the complexity of the profession, therefore, only by hard work for several years can you become a real specialist. True, such an increased tariff schedule is not set at all enterprises.

There is one more profession, the adjuster of instrumentation and automation. His qualifications are slightly higher than that of a simple locksmith. Therefore, the installer must be at least IV category. This qualification is awarded after several years of successful conscientious work, it can be said for special merits.

Material reward

As one of the literary characters said: "All work must be paid." But is the work of the instrument mechanic well paid? First of all, we are talking about being at the right place at the right time: if in Moscow the salary of a control and automation engineer is quite large, then in some Mukhoboev it is completely different, naturally, downward.If this place is an enterprise in the oil and gas sector or metallurgy, then the salary will be much higher than at engineering enterprises. So all at once we go to get a job in Gazprom! But there is probably not enough space for everyone ...

In general, the wages of a fitter of instrumentation and automation are at or slightly higher electricians salary, mechanics, gas workers. In addition, when hiring a scarce specialist in instrumentation and automation, especially in the presence of work experience, an increased level is established, or a personal addition to the salary.

As mentioned above, modern instrumentation and automation equipment has to be programmed more often than repaired. Therefore, often the instrumentation and automation departments are transformed into departments of process control systems, where, if there is a desire and ability, the employees of the instrumentation and control departments are transferred. And the material remuneration of labor in these departments, as a rule, is slightly higher.

In addition, a good specialist in instrumentation and automation can always work part-time. This can be maintenance of water and heat energy meters, simple automation of small enterprises, mini-boiler houses. In the presence of an electrical safety group, it is quite possible to work as an electrician: well, just “screw the bulbs” somewhere. Although, to tell the truth, a person should earn enough in one place. That's just, unfortunately, all of these places are not enough.

Boris Aladyshkin

An example from the work of a mechanic of instrumentation and automation:Upgrading a gate valve or reversing capacitor motor

See also at i.electricianexp.com

: