Categories: Auto electrician

Number of views: 2092

Comments on the article: 0

What batteries are used in modern electric vehicles

The electric car is the most modern vehicle, and motorists are increasingly transplanting them in many countries of the world. About a million people around the world are actively using electric cars, because unlike traditional cars that run on combustible fuel, the electric car is more economical to operate and generally more practical.

However, when changing the vehicle to electric, the driver will inevitably have questions regarding maintenance, repair, cost batteries etc. Despite all these questions, it turns out that electric cars ultimately still have a number of advantages over conventional cars. And in this article we will talk specifically about batteries for electric cars.

So, electric cars are cars that use electric energy stored in the battery for their drive. This technology allows you to make an electric car twice as cheap in operation, compared with a car on gasoline, as well as more maneuverability on the road. Already today there are several types of batteries for electric cars: lithium-ion, lithium-sulfur, aluminum-ion and metal-air.

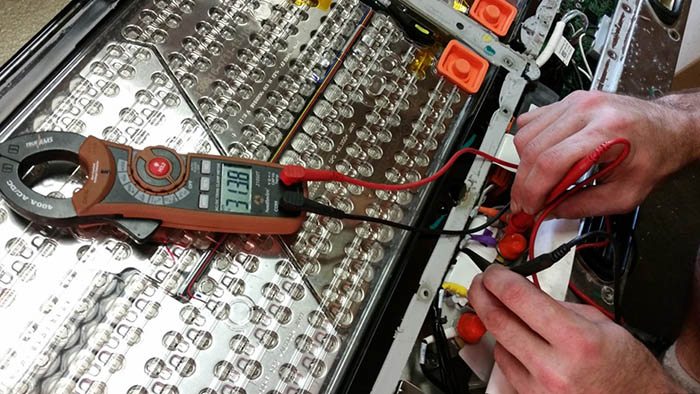

If necessary, any battery can be replaced, for this it is enough to drive the electric car into a specialized car service. The wizard will correctly connect all the connectors, establish the connection of the battery with the on-board computer, make appropriate software settings that will allow the electric machine to work as before. As for the "refueling" with electricity, today in the world there are already charging stations for electric cars with a capacity of 350 kW.

Lithium batteries

To date, the most popular batteries for electric cars of two types: lithium-ion and metal-air. They do not require maintenance during the year, and often the operation of the electric car is uninterrupted and lengthy with them.

Of course, lithium-ion batteries are the most commonly installed battery option, simply due to a number of obvious advantages: a fairly high energy density, high voltage, low self-discharge (maximum 20% per year and 6% per month), lack of memory effect, and the useful life is up to 10 years.

Such batteries are expensive, and not every car enthusiast can afford them (it depends, among other things, on the brand of car). Of course, there are other drawbacks: the range of operating temperatures from -20 to +50 ° C causes the risk of overheating of the battery, plus exposure to overcharge.

Metal Air Batteries

Metal-air batteries appeared on the market not so long ago, but are already in good demand among fans of electric cars. At the moment, it can be argued that such batteries are quite durable and of high quality. In addition, they are compact, lightweight, inexpensive, easy to dispose of, and at the same time provide the vehicle with optimal mileage. The disadvantages include: a sudden stop, the need for a high-quality filter, sensitivity to low temperatures.

Lithium sulfur batteries

Lithium-sulfur batteries for electric cars are low-maintenance batteries, but they withstand up to 60 charge-discharge cycles. The technology is being finalized, improved to make lithium-sulfur batteries more efficient, and generally considered very promising.

Many companies are working on batteries of this type, and promise to achieve significant progress by 2020. Battery on this basis have increased capacity and a wider range of operating temperatures, compared with lithium-ion batteries.The main obstacle that must now be overcome is the small number of charge-discharge cycles.

Aluminum-ion batteries

Least of all users of electric cars are aluminum-ion batteries, since they still have few charge-discharge cycles and poor cathode performance. Accordingly, the demand for them is minimal. Now Chinese developers are trying to improve aluminum-ion batteries, and there is reason to believe that in the future they will be used more actively. Aluminum-ion batteries are considered safer and promise to be cheaper.

In an electric car, as a rule, a separate battery is used to power the on-board network. The traction battery serves only to power the electric motor, therefore it is precisely the traction battery that has more stringent requirements regarding power and durability, because it is thanks to it and the electric drive fed from it that electric cars are so maneuverable in comparison with gasoline ones.

The best battery technology for electric cars

The power of the electric motor in the electric car should always be provided at the highest level, so improvements are always made in the technology of creating batteries. Great expectations are now placed on graphene - a special form of carbon. It is inexpensive to manufacture, and the battery with it is four times cheaper than lithium.

Many countries are already manufacturing graphene-based traction batteries. In theory, charging for 1000 kilometers will take only about 8 minutes. In the near future, graphene batteries will unambiguously make themselves known in practice, especially in Germany electric cars have already successfully tested them.

Batteries for electric cars today

So far, most batteries installed in electric cars are lithium-ion, iron-phosphate and lead-acid. Batteries of any type are assembled in the form of cells connected in parallel and in series to huge assemblies of the required capacity.

Since electric cars differ in power, the batteries are not the same, that is, they consist of a different number of cells. On some models, the traction battery voltage is less than 400 volts; on others, 800.

The new battery is designed for a long period of operation, and its full charge is enough for maximum mileage, but over time, the battery wears out and needs to be replaced. And in case of damage to some cells, the modular design of the battery allows you to repair it.

And here it is important to understand that the selection of a new battery, in case of exhaustion, is made individually, the on-board computer is also programmed accordingly. Moreover, the repair and replacement of the battery is done by a master with a specialized education.

Initially, the life of a traction battery of an electric car is limited by the period of its operation declared by the manufacturer, it is usually from 5 to 10 years, depending on the model of the product. Over time, the average battery capacity decreases: in the first couple of years, it loses up to 10% of capacity, then - up to 20% in three years, and then - 1% per year. One way or another, at some point the battery will inevitably have to be changed. But to have a spare battery on hand for many years is not necessary.

Used batteries from electric cars are not thrown away. They are often arranged in autonomous home solar power systems, which is very practical. If the battery is no longer needed, it should be disposed of correctly and safely for the environment, usually the battery manufacturers themselves do it.

See also:

Tesla Supercharger Power Supplies

How does an unmanned car work and how

The 10 best battery technologies for charging and storing future energy

See also at i.electricianexp.com

: